Silicon carbide (SiC) e le gata o se tekinolosi taua mo le puipuiga o le atunuu ae o se mea taua foi mo le lalolagi atoa taavale ma alamanuia malosi. I le avea ai ma laasaga taua muamua i le SiC faʻapipiʻi faʻamaʻi taʻitoʻatasi, o le tipi saʻo e fuafua saʻo ai le lelei o le manifinifi ma le faʻailo mulimuli ane. O auala fa'aleaga masani e masani ona fa'aalia ai ta'eta'ei luga ma lalo, fa'ateleina le gau o le wafer ma tau o le gaosiga. O le mea lea, o le puleaina o le faaleagaina o luga e taua tele mo le faʻalauteleina o le gaosiga o masini SiC.

I le taimi nei, o le SiC ingot slicing e feagai ma luitau tetele e lua:

- Tu'umau meafaitino i le va'aiga tele-uaea masani:O le ma'a'a tele o le SiC ma le ma'ale'ale e faigofie ai ona fe'ai ma ta'e a'o tipi, olo, ma fa'aiila. E tusa ai ma faamatalaga Infineon, reciprocating masani reciprocating taimane-resin-fusia tele-uaea sawing ausia na o le 50% faʻaaogaina meafaitino i le tipiina, faatasi ai ma le aofaʻi tasi-wafer gau oʻo atu ~ 250 μm ina ua uma ona polesi, tuua itiiti mea aoga.

- Le maualalo le lelei ma le umi o le gaosiga o taamilosaga:O fa'amaumauga fa'ava-o-malo o lo'o fa'aalia ai o le gaosiga o 10,000 wafers e fa'aaoga ai le 24-itula fa'aauau pea ili uaea e mana'omia le 273 aso. O lenei metotia e mana'omia ai meafaigaluega tetele ma mea e fa'aaogaina a'o fa'atupuina le gaoa ma le filogia (pefu, suavai leaga).

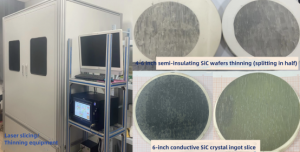

Ina ia foia nei mataupu, o le 'au a Polofesa Xiu Xiangqian i le Iunivesite o Nanjing, ua latou fausia ni meafaigaluega faʻapipiʻi leisa maualuga mo le SiC, faʻaaogaina le tekonolosi laser ultrafast e faʻaitiitia ai faʻaletonu ma faʻaleleia le gaosiga. Mo le 20-mm SiC ingot, o lenei tekinolosi e faʻaluaina le fua o le wafer pe a faʻatusatusa i le ili uaea masani. E le gata i lea, o faʻamaʻi faʻapipiʻi leisa o loʻo faʻaalia ai le maualuga o le tulaga tutusa, e mafai ai ona faʻaititia le mafiafia i le 200 μm i le wafer ma faʻateleina le gaosiga.

Tulaga Autu:

- Ua mae'a le su'esu'ega i masini fa'ata'ita'i lapopo'a, fa'amaonia mo le tipiina 4-6-inisi semi-insulating wafers SiC ma 6-inisi conductive SiC ingots.

- 8-inisi ingot slicing o loʻo faʻamaonia.

- Fa'ato'a pu'upu'u le taimi fa'a'oti, maualuga fa'aletausaga fa'aletausaga, ma >50% fa'aleleia atili.

XKH's SiC mea'ai o le ituaiga 4H-N

Avanoa Maketi:

O meafaigaluega nei ua sauni e avea ma fofo autu mo le 8-inisi SiC ingot slicing, o loʻo pulea nei e Iapani faʻaulufale mai ma le maualuga o tau ma faʻatau atu. Ole mana'oga ile atunu'u mo mea faigaluega fa'ama'i/ti'oti leisa e sili atu ile 1,000 iunite, peita'i e leai ni isi mea fa'aSaina matutua. O tekinolosi a le Iunivesite o Nanjing o loʻo i ai le tele o tau maketi ma le tamaoaiga.

Tele-Material Fegalegaleaiga:

I tua atu o le SiC, o meafaigaluega e lagolagoina le faʻaogaina o le laser o le gallium nitride (GaN), alumini oxide (Al₂O₃), ma taimane, faʻalauteleina ana talosaga tau alamanuia.

E ala i le fa'afouina o le SiC wafer processing, o lenei fa'afouga e fa'afeiloa'i ai fa'amaua'iga taua i le gaosiga o semiconductor a'o fa'aogatasi ma faiga fa'alelalolagi aga'i i mea e fa'atino maualuga, fa'asao le malosi.

Fa'ai'uga

I le avea ai ma taʻitaʻi o pisinisi i le gaosiga o meaʻai silicon carbide (SiC), e faʻapitoa le XKH i le tuʻuina atu o 2-12-inisi siC substrates (e aofia ai le 4H-N/SEMI-type, 4H/6H/3C-type) e faʻatatau i le maualuga o le tuputupu aʻe o vaega e pei o taavale malosi fou (NEVs) eletise (PVs), faʻamatalaga eletise. O le faʻaaogaina o le tele-dimension wafer low-loss slicing technology, ma le maualuga-saʻo le gaosiga o tekonolosi, ua matou ausia le tele o gaosiga o 8-inisi substrates ma faʻalavelave i le 12-inisi conductive SiC crystal growth technology, e matua faʻaitiitia ai le tau o tupe taʻitasi. I le agai i luma, o le a faʻaauau pea le faʻaogaina o le laser slicing ma le atamai faʻatonuina faiga e faʻaleleia ai le 12-inisi substrate fua i tulaga faʻatauvaʻa i le lalolagi atoa, faʻamalosia le pisinisi SiC i totonu o le atunuʻu e talepeina monopolies faavaomalo ma faʻavavevave talosaga i vaega maualuga e pei o meataavale eletise ma AI server power supply.

XKH's SiC mea'ai o le ituaiga 4H-N

Taimi meli: Aukuso-15-2025