SiC wafer's abstract

Silicon carbide (SiC) wafersua avea ma sui o filifiliga mo eletise maualuga-maualuga, maualuga-telefoni, ma maualuga-vevela i totonu o taʻavale, malosi faʻafouina, ma aerospace. O la matou faila e aofia ai polytypes autu ma faiga faʻapipiʻi - nitrogen-doped 4H (4H-N), high-purity semi-insulating (HPSI), nitrogen-doped 3C (3C-N), ma le p-type 4H / 6H (4H / 6H-P) - ofo atu i ni togi lelei se tolu: PRIME (faʻaiila atoatoa, masini-grades (faʻagasologa) faʻataʻitaʻiga, Dpolished masini (substrates) SU'ESU'EGA (fa'ailoga epi fa'apitoa ma fa'amatalaga o le doping mo su'esu'ega ma su'esu'ega). E 2″, 4″, 6″, 8″, ma le 12″ e fa'atatau i mea faigaluega fa'aleaganu'u ma mea fa'aola. Matou te tu'uina atu fo'i fa'aliga fa'a-monocrystalline ma tioata fa'atatau tonu o fatu e lagolago ai le tuputupu a'e tioata i totonu o le fale.

O tatou 4H-N wafers faʻaalia densities ave mai le 1 × 10¹⁶ i le 1 × 10¹⁹ cm⁻³ ma resistivities o 0.01-10 Ω·cm, tuuina atu eletonika sili mobility ma malepelepe fanua i luga 2 MV/cm-lelei mo Schottky diodes, MOSFETs. HPSI mea'ai e sili atu i le 1×10¹² Ω·cm resistivity ma micropipe densities i lalo ole 0.1 cm⁻², fa'amautinoa le la'ititi o le tafe mo masini RF ma microwave. Cubic 3C-N, avanoa i le 2″ ma le 4″ formats, e mafai ai le heteroepitaxy i luga o le silikoni ma lagolagoina ata fou photonic ma MEMS talosaga. P-ituaiga 4H/6H-P wafers, faʻapipiʻi i le alumini i le 1 × 10¹⁶–5 × 10¹⁸ cm⁻³, faʻafaigofie le faʻaogaina o masini faʻapipiʻi.

SiC wafers, PRIME wafers e fa'amamaina fa'ama'i-mekanika e o'o i le <0.2 nm RMS fa'aliga lau'ele'ele, fesuiaiga atoa mafiafia i lalo ole 3 µm, ma le aufana <10 µm. DUMMY substrates e faatelevaveina le fa'apotopotoga ma su'ega afifiina, ae o RESEARCH wafers e fa'aalia ai le mafiafia o le epi-layer o le 2-30 µm ma le doping fa'apitoa. O oloa uma e faʻamaonia e le X-ray diffraction (rocking curve <30 arcsec) ma Raman spectroscopy, faʻatasi ai ma suʻega eletise-Hall measurements, C-V profiling, ma micropipe scanning-faʻamautinoa le tausisia o le JEDEC ma le SEMI.

O pa'u e oo atu i le 150 mm le lautele o lo'o fa'atupuina e ala i le PVT ma le CVD fa'atasi ai ma va'aiga ta'ape i lalo ole 1×10³ cm⁻² ma maualalo le aofa'i ole paipa. O tioata fatu e tipiina i totonu ole 0.1° o le c-axis e faʻamautinoa ai le toe faʻaleleia o le tuputupu aʻe ma le maualuga o le seleselega.

E ala i le tu'ufa'atasia o le tele o polytypes, doping variants, quality grades, SiC wafer sizes, and in-house boule and seed-crystal production, our SiC substrate platform streamlines supply chains ma faatelevaveina le atina'eina o masini mo taavale eletise, smart grids, ma fa'aoga si'osi'omaga faigata.

SiC wafer's abstract

Silicon carbide (SiC) wafersua avea ma SiC substrate o filifiliga mo le malosi-maualuga, maualuga-televave, ma le maualuga-vevela eletise i luga o taʻavale, malosi faʻafouina, ma aerospace vaega. O la matou faila o loʻo aofia ai polytypes autu ma faiga faʻapipiʻi - nitrogen-doped 4H (4H-N), semi-insulating maualuga-mama (HPSI), nitrogen-doped 3C (3C-N), ma le p-type 4H / 6H (4H / 6H-P) - ofo atu i togi lelei e tolu: SiC waferPRIME (fa'alelei atoatoa, mea'ai-vaega masini), DUMMY (lafu po'o le fa'apolopolo mo fa'ata'ita'iga fa'agaioiga), ma RESEARCH (fa'ailoga epi masani ma fa'amatalaga doping mo R&D). SiC Wafer diameters e 2″, 4″, 6″, 8″, ma le 12″ e fetaui ma mea faigaluega fa'aleaganu'u ma mea fa'apitoa. Matou te tu'uina atu fo'i fa'aliga fa'a-monocrystalline ma tioata fa'atatau tonu o fatu e lagolago ai le tuputupu a'e tioata i totonu o le fale.

O tatou 4H-N SiC wafers faʻaalia densities feaveaʻi mai 1 × 10¹⁶ i 1 × 10¹⁹ cm⁻³ ma resistivities o 0.01-10 Ω·cm, tuuina atu eletonika sili ona lelei ma malepe fanua i luga 2 MV/cm-lelei mo Schottky diodes, ma, MOSFETky diodes. HPSI mea'ai e sili atu i le 1×10¹² Ω·cm resistivity ma micropipe densities i lalo ole 0.1 cm⁻², fa'amautinoa le la'ititi o le tafe mo masini RF ma microwave. Cubic 3C-N, avanoa i le 2″ ma le 4″ formats, e mafai ai le heteroepitaxy i luga o le silikoni ma lagolagoina ata fou photonic ma MEMS talosaga. SiC wafer P-ituaiga 4H/6H-P wafers, faʻapipiʻi i le alumini i le 1 × 10¹⁶–5 × 10¹⁸ cm⁻³, faʻafaigofie le fausiaina o masini faʻapipiʻi.

SiC wafer PRIME wafers e fa'amama fa'ama'i-mekanika e o'o i le <0.2 nm RMS fa'aliga lau'ele'ele, suiga atoa mafiafia i lalo ole 3 µm, ma le aufana <10 µm. DUMMY substrates e faatelevaveina le fa'apotopotoga ma su'ega afifiina, ae o RESEARCH wafers e fa'aalia ai le mafiafia o le epi-layer o le 2-30 µm ma le doping fa'apitoa. O oloa uma e faʻamaonia e le X-ray diffraction (rocking curve <30 arcsec) ma Raman spectroscopy, faʻatasi ai ma suʻega eletise-Hall measurements, C-V profiling, ma micropipe scanning-faʻamautinoa le tausisia o le JEDEC ma le SEMI.

O pa'u e oo atu i le 150 mm le lautele o lo'o fa'atupuina e ala i le PVT ma le CVD fa'atasi ai ma va'aiga ta'ape i lalo ole 1×10³ cm⁻² ma maualalo le aofa'i ole paipa. O tioata fatu e tipiina i totonu ole 0.1° o le c-axis e faʻamautinoa ai le toe faʻaleleia o le tuputupu aʻe ma le maualuga o le seleselega.

E ala i le tu'ufa'atasia o le tele o polytypes, doping variants, quality grades, SiC wafer sizes, and in-house boule and seed-crystal production, our SiC substrate platform streamlines supply chains ma faatelevaveina le atina'eina o masini mo taavale eletise, smart grids, ma fa'aoga si'osi'omaga faigata.

6inch 4H-N type SiC wafer's pepa fa'amaumauga

| 6inch SiC wafers pepa fa'amaumauga | ||||

| Parameter | Laiti Parameter | Z Vasega | P Vasega | D Vasega |

| Diamita | 149.5–150.0 mm | 149.5–150.0 mm | 149.5–150.0 mm | |

| mafiafia | 4H‑N | 350 µm ± 15 µm | 350 µm ± 25 µm | 350 µm ± 25 µm |

| mafiafia | 4H‑SI | 500 µm ± 15 µm | 500 µm ± 25 µm | 500 µm ± 25 µm |

| Fa'asinomaga ole Wafer | Tu'u ese: 4.0° agai i le <11-20> ±0.5° (4H-N); I luga ole axis: <0001> ±0.5° (4H-SI) | Tu'u ese: 4.0° agai i le <11-20> ±0.5° (4H-N); I luga ole axis: <0001> ±0.5° (4H-SI) | Tu'u ese: 4.0° agai i le <11-20> ±0.5° (4H-N); I luga ole axis: <0001> ±0.5° (4H-SI) | |

| Micropipe Density | 4H‑N | ≤ 0.2 cm⁻² | ≤ 2 cm⁻² | ≤ 15 cm⁻² |

| Micropipe Density | 4H‑SI | ≤ 1 cm⁻² | ≤ 5 cm⁻² | ≤ 15 cm⁻² |

| Tete'e | 4H‑N | 0.015–0.024 Ω·cm | 0.015–0.028 Ω·cm | 0.015–0.028 Ω·cm |

| Tete'e | 4H‑SI | ≥ 1×10¹⁰ Ω·cm | ≥ 1×10⁵ Ω·cm | |

| Primary Flat Orientation | [10-10] ± 5.0° | [10-10] ± 5.0° | [10-10] ± 5.0° | |

| Primary Flat Umi | 4H‑N | 47.5 mm ± 2.0 mm | ||

| Primary Flat Umi | 4H‑SI | Notch | ||

| Tuusaunoaga Tupito | 3 mm | |||

| Warp/LTV/TTV/Bow | ≤2.5 µm / ≤6 µm / ≤25 µm / ≤35 µm | ≤5 µm / ≤15 µm / ≤40 µm / ≤60 µm | ||

| Talatala | Polish | Ra ≤ 1 nm | ||

| Talatala | CMP | Ra ≤ 0.2 nm | Ra ≤ 0.5 nm | |

| Ta'eta'e pito | Leai | Umi fa'aputu ≤ 20 mm, tasi ≤ 2 mm | ||

| Papatusi Hex | Vaega fa'aopoopo ≤ 0.05% | Vaega fa'aopoopo ≤ 0.1% | Vaega fa'aopoopo ≤ 1% | |

| Polytype Areas | Leai | Vaega fa'aopoopo ≤ 3% | Vaega fa'aopoopo ≤ 3% | |

| Fa'aaofia Carbon | Vaega fa'aopoopo ≤ 0.05% | Vaega fa'aopoopo ≤ 3% | ||

| Mata'i Laufanua | Leai | Fa'aputuga umi ≤ 1 × fa'ameamea le lautele | ||

| Tipi Chips | Leai se faatagaina ≥ 0.2 mm lautele & loloto | E oʻo atu i le 7 meataalo, ≤ 1 mm taʻitasi | ||

| TSD (Ta'u'ese'ese le Siu fa'asolo) | ≤ 500 cm⁻² | N/A | ||

| BPD (Va'ega Fa'avae Va'alele) | ≤ 1000 cm⁻² | N/A | ||

| Fa'aleagaina i luga | Leai | |||

| afifiina | Kaseti fa'ama'i fa'atele po'o se atigipusa masimea ta'itasi | Kaseti fa'ama'i fa'atele po'o se atigipusa masimea ta'itasi | Kaseti fa'ama'i fa'atele po'o se atigipusa masimea ta'itasi | |

4inch 4H-N type SiC wafer's pepa fa'amaumauga

| 4insi SiC wafer's pepa fa'amaumauga | |||

| Parameter | Zero MPD Gaosiga | Vasega Gaosia Fa'ata'atia (Visi P) | Vasega Fa'ata (vaega D) |

| Diamita | 99.5 mm–100.0 mm | ||

| Mafiafia (4H-N) | 350 µm±15 µm | 350 µm±25 µm | |

| Mafiafia (4H-Si) | 500 µm±15 µm | 500 µm±25 µm | |

| Fa'asinomaga ole Wafer | Tu'u ese: 4.0° agai i le <1120> ± 0.5° mo 4H-N; I luga o le axis: <0001> ± 0.5 ° mo 4H-Si | ||

| Malosi ole paipa (4H-N) | ≤0.2 cm⁻² | ≤2 cm⁻² | ≤15 cm⁻² |

| Malosi ole paipa (4H-Si) | ≤1 cm⁻² | ≤5 cm⁻² | ≤15 cm⁻² |

| Tete'e (4H-N) | 0.015–0.024 Ω·cm | 0.015–0.028 Ω·cm | |

| Tete'e (4H-Si) | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |

| Primary Flat Orientation | [10-10] ±5.0° | ||

| Primary Flat Umi | 32.5 mm ±2.0 mm | ||

| Lua Mafolafola Umi | 18.0 mm ±2.0 mm | ||

| Tulaga Lua mafolafola | Silisi fa'asaga i luga: 90° CW mai le tulaga maualuga ±5.0° | ||

| Tuusaunoaga Tupito | 3 mm | ||

| LTV/TTV/aufana | ≤2.5 µm/≤5 µm/≤15 µm/≤30 µm | ≤10 µm/≤15 µm/≤25 µm/≤40 µm | |

| Talatala | Polani Ra ≤1 nm; CMP Ra ≤0.2 nm | Ra ≤0.5 nm | |

| Ta'eta'e Tu'u I le Malamalama Maualuluga | Leai | Leai | Fa'aputuga umi ≤10 mm; umi tasi ≤2 mm |

| Papatusi Hex I Malamalama Maualuga Maualuga | Vaega fa'aopoopo ≤0.05% | Vaega fa'aopoopo ≤0.05% | Vaega fa'aopoopo ≤0.1% |

| Polytype Areas I le Malamalama Maualuga | Leai | Vaega fa'aopoopo ≤3% | |

| Vaaiga Carbon Inclusions | Vaega fa'aopoopo ≤0.05% | Vaega fa'aopoopo ≤3% | |

| Su'ega Sili Sili I luga o le Malamalama Maualuga | Leai | Le umi fa'aputu ≤1 le lautele o fafie | |

| Tipi Chips E Malamalama Malosi Maualuga | Leai se fa'atagaina ≥0.2 mm le lautele ma le loloto | 5 faatagaina, ≤1 mm taitasi | |

| Silicon Surface Contamination E le Malamalama Maualuga | Leai | ||

| Fa'ase'e fa'avili fa'a filo | ≤500 cm⁻² | N/A | |

| afifiina | Kaseti fa'ama'i fa'atele po'o se atigipusa masimea ta'itasi | Kaseti fa'ama'i fa'atele po'o se atigipusa masimea ta'itasi | Kaseti fa'ama'i fa'atele po'o se atigipusa masimea ta'itasi |

4inisi HPSI ituaiga SiC wafer's pepa fa'amaumauga

| 4inisi HPSI ituaiga SiC wafer's pepa fa'amaumauga | |||

| Parameter | Zero MPD Vasega Gaosia (Visi Z) | Vasega Gaosia Fa'ata'atia (Visi P) | Vasega Fa'ata (vaega D) |

| Diamita | 99.5–100.0 mm | ||

| Mafiafia (4H-Si) | 500 µm ±20 µm | 500 µm ±25 µm | |

| Fa'asinomaga ole Wafer | Tu'u ese: 4.0° agai i le <11-20> ±0.5° mo 4H-N; I luga o le axis: <0001> ± 0.5 ° mo 4H-Si | ||

| Malosi ole paipa (4H-Si) | ≤1 cm⁻² | ≤5 cm⁻² | ≤15 cm⁻² |

| Tete'e (4H-Si) | ≥1E9 Ω·cm | ≥1E5 Ω·cm | |

| Primary Flat Orientation | (10-10) ±5.0° | ||

| Primary Flat Umi | 32.5 mm ±2.0 mm | ||

| Lua Mafolafola Umi | 18.0 mm ±2.0 mm | ||

| Tulaga Lua mafolafola | Silisi fa'asaga i luga: 90° CW mai le tulaga maualuga ±5.0° | ||

| Tuusaunoaga Tupito | 3 mm | ||

| LTV/TTV/aufana | ≤3 µm/≤5 µm/≤15 µm/≤30 µm | ≤10 µm/≤15 µm/≤25 µm/≤40 µm | |

| Talatala (C foliga) | Polish | Ra ≤1 nm | |

| Talatala (Si foliga) | CMP | Ra ≤0.2 nm | Ra ≤0.5 nm |

| Ta'eta'e Tu'u I le Malamalama Maualuluga | Leai | Fa'aputuga umi ≤10 mm; umi tasi ≤2 mm | |

| Papatusi Hex I Malamalama Maualuga Maualuga | Vaega fa'aopoopo ≤0.05% | Vaega fa'aopoopo ≤0.05% | Vaega fa'aopoopo ≤0.1% |

| Polytype Areas I le Malamalama Maualuga | Leai | Vaega fa'aopoopo ≤3% | |

| Vaaiga Carbon Inclusions | Vaega fa'aopoopo ≤0.05% | Vaega fa'aopoopo ≤3% | |

| Su'ega Sili Sili I luga o le Malamalama Maualuga | Leai | Le umi fa'aputu ≤1 le lautele o fafie | |

| Tipi Chips E Malamalama Malosi Maualuga | Leai se fa'atagaina ≥0.2 mm le lautele ma le loloto | 5 faatagaina, ≤1 mm taitasi | |

| Silicon Surface Contamination E le Malamalama Maualuga | Leai | Leai | |

| Fa'a'ese'ese le fa'a siu filo | ≤500 cm⁻² | N/A | |

| afifiina | Kaseti fa'ama'i fa'atele po'o se atigipusa masimea ta'itasi | ||

SiC wafer's talosaga

-

SiC Wafer Power Modules mo EV Inverters

MOSFETs ma diodes fa'avae SiC fa'avae i luga o mea fa'apipi'i siC sili ona lelei e fa'aolaina ai le gau tele o suiga. E ala i le fa'aogaina o le SiC wafer technology, o nei masini eletise e fa'agaoioia i le maualuga o voltage ma le vevela, e mafai ai ona sili atu le lelei o le fa'aliliuina o le traction. O le tuʻufaʻatasia o le SiC wafer e mate i tulaga eletise e faʻaitiitia ai manaʻoga malulu ma tulagavae, faʻaalia ai le gafatia atoatoa o le SiC wafer fou. -

Meafaigaluega RF ma 5G i luga ole SiC Wafer

RF amplifiers ma ki ua fau i luga o semi-insulating SiC wafer platforms e fa'aalia ai le maualuga o le fa'avevelaina ma le gau gau. O le SiC wafer substrate e faʻaitiitia ai le gau i le GHz, ae o le malosi o le SiC wafer e mafai ai ona faʻagaioia le faʻaogaina i lalo o le malosi maualuga, tulaga maualuga o le vevela-ma avea ai le SiC wafer ma mea e filifilia mo le isi-gen 5G base stations ma radar system. -

Optoelectronic & LED Substrates mai SiC Wafer

O moli lanu moana ma le UV ua fa'atupuina i luga ole SiC wafer substrates e aoga mai le fetaui lelei o lattice ma le fa'amama'i vevela. O le fa'aogaina o le fa'a'ai C-foliga SiC e fa'amautinoa ai le tutusa o le epitaxial layers, ae o le ma'a'a o le SiC wafer e mafai ai ona fa'amama fa'alelei lelei ma fa'amautinoa le afifiina o masini. O le mea lea e fa'aogaina ai le SiC o lo'o fa'asolo i luga o le fa'avae mo fa'aoga o le LED e maualuga le malosi, umi le ola.

SiC wafer's Q&A

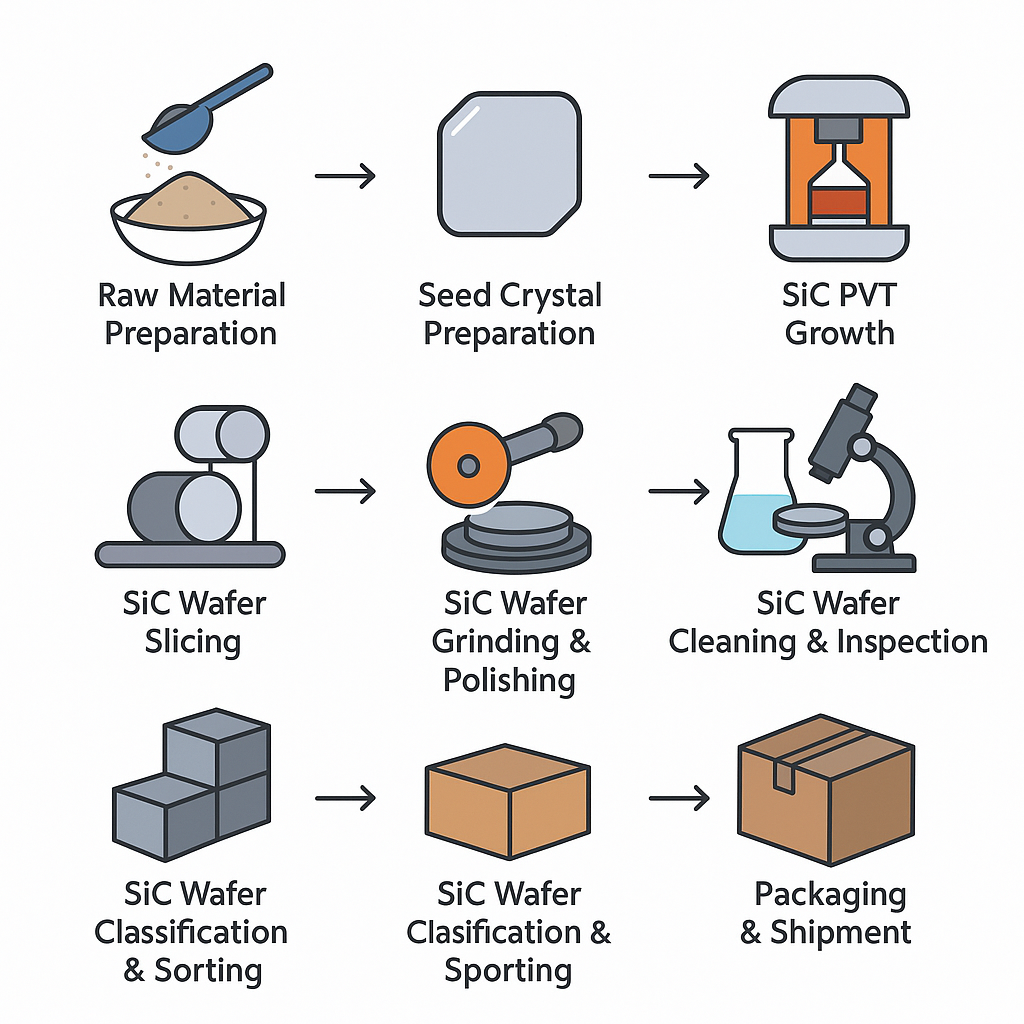

1. F: E fa'afefea ona gaosia siC wafers?

A:

SiC wafers gaosiaLaasaga Auiliili

-

SiC wafersSauniuniga o Mea Mata

- Fa'aaogā le pa'u SiC ≥5N-grade (mea leaga ≤1 ppm).

- Fa'amama ma mua'i tao e aveese le kaponi o totoe po'o mea fa'atosina.

-

SiCSauniuniga tioata o fatu

-

Ave se fasi tioata 4H-SiC tasi, tipi i luga o le 〈0001〉 faʻatonuga i le ~ 10 × 10 mm².

-

Fa'apolopolo sa'o i le Ra ≤0.1 nm ma fa'ailoga fa'ailoga tioata.

-

-

SiCPVT Fa'atupulaia (Va'aiga Ausa Faaletino)

-

U'u le ipu kalafi: pito i lalo ma le pauta SiC, pito i luga ma tioata fatu.

-

Aveese i le 10⁻³–10⁻⁵ Torr po'o le toe fa'atumu i le helium mama maualuga ile 1 atm.

-

Sone puna vevela i le 2100–2300 ℃, tausia sone fatu 100–150 ℃ cooler.

-

Pulea le fua o le tuputupu aʻe ile 1-5 mm/h e faapaleni ai le lelei ma le gaosiga.

-

-

SiCIngot Annealing

-

Fa'alili le SiC ua tupu i le 1600-1800 ℃ mo le 4-8 itula.

-

Fa'amoemoega: fa'amāmā ma fa'aitiitia le mamafa o le ta'ese.

-

-

SiCOsi'isi'i

-

Fa'aaoga se uaea taimane e tipi ai le ingot ile 0.5-1 mm mafiafia mafi.

-

Fa'aiti'itia le vibration ma le malosi i tua e 'alofia ai ni ta'eta'ei.

-

-

SiCWaferFa'aliga & Faila

-

Omea mamafae aveese mea leaga o le ili (gatala ~10–30 µm).

-

olo leleiia maua le mafolafola ≤5 µm.

-

Fa'aliga Fa'ainisinia (CMP)e oʻo atu i faʻata-pei o le maeʻa (Ra ≤0.2 nm).

-

-

SiCWaferFa'amamaina & Asiasiga

-

Fa'amamaina ole Ultrasonici le vaifofo Piranha (H₂SO₄:H₂O₂), DI vai, sosoo ai ma le IPA.

-

XRD/Raman spectroscopye faʻamaonia polytype (4H, 6H, 3C).

-

Interferometrye fuaina le mafolafola (<5 µm) ma le taua (<20 µm).

-

Su'esu'e fa-fae fa'ata'ita'i le resistivity (eg HPSI ≥10⁹ Ω·cm).

-

Su'ega fa'aletonui lalo polarized malamalama microscope ma valu su'ega.

-

-

SiCWaferFa'avasegaina & Fa'avasega

-

Fa'avasega fasipepa i polytype ma le eletise:

-

4H-SiC N-ituaiga (4H-N): fa'aogaina o le avefe'au 10¹⁶–10¹⁸ cm⁻³

-

4H-SiC High Purity Semi-Insulating (4H-HPSI): resistivity ≥10⁹ Ω·cm

-

6H-SiC N-ituaiga (6H-N)

-

Isi: 3C-SiC, P-ituaiga, ma isi.

-

-

-

SiCWaferafifiina & La'uina

2. F: O a ni mea taua o le SiC wafers i luga ole silicon wafers?

A: A fa'atusatusa i le silicon wafers, SiC wafers e mafai ai:

-

Fa'agaioiga eletise maualuga(> 1,200 V) faʻatasi ai ma le faʻaitiitia i luga ole tetee.

-

Maualuluga o le vevela(>300 °C) ma fa'aleleia atili le pulea o le vevela.

-

Saosaoa suiga vavefa'atasi ai ma le fa'aitiitia o suiga, fa'aitiitia ai le fa'amalieina o le fa'aogaina ma le lapopo'a i mea fa'aliliu eletise.

4. F: O a faʻafitauli masani e aʻafia ai SiC wafer yield ma faʻatinoga?

A: O fa'aletonu muamua ile SiC wafers e aofia ai micropipes, va'alele va'alele (BPDs), ma masiosi'i luga. Micropipes e mafai ona mafua ai le faaletonu o masini; BPD faʻateleina i luga o le tetee ile taimi; ma maosiosia i luga e ta'i atu ai i le ma'i masi pe leaga le tuputupu a'e o le epitaxial. O le su'esu'ega malosi ma le fa'aitiitia o fa'aletonu e mana'omia e fa'ateleina ai le fua o le siC wafer.

Taimi meli: Iuni-30-2025