Lisi o Mataupu

1.Autu Autu ma le Taua ole Faamamaina ole Wafer

2. Su'esu'ega Fa'aleaga ma Tekinolosi Au'ili'ili

3. Metotia Fa'amama Fa'asili ma Ta'iala Fa'ainisinia

4. Fa'atinoga Fa'atekinisi ma Fa'atonuga Fa'atonu Fa'atonu

5.Fesuiaiga i le lumanaʻi ma Taʻiala Fou

6.XKH Fa'ai'uga Fa'ai'uga Fofo ma Auaunaga Fa'anatura

O le fa'amamāina o wafer ose faiga fa'atauva'a i le gaosiga o semiconductor, e o'o lava i fa'ama'i fa'aatomika e mafai ona fa'aleagaina ai le fa'atinoga o masini po'o le fua mai. O le fa'amamāina e masani lava ona aofia ai le tele o laasaga e aveese ai mea leaga eseese, e pei o toega oona, fa'aleaga mea'ai, mea'ai, ma oxides masani.

1. Manulauti ole Faamamaina ole Wafer

- Ave'ese mea fa'aleagaina (fa'ata'ita'iga, toega photoresist, tamatamai lima).

- Ave'ese mea fa'aleaga u'amea (fa'ata'ita'iga, Fe, Cu, Ni).

- Ave'ese mea fa'aleaga (fa'ata'ita'iga, pefu, fasi kasa).

- Ave'ese oxides (fa'ata'ita'iga, SiO₂ apa na fa'atupu a'o fa'aalia le ea).

2. Taua ole Fa'amama Fa'amama Wafer

- Faʻamautinoa le maualuga o le gaosiga o gaioiga ma le faʻatinoga o masini.

- Faʻaitiitia le faʻaletonu ma le tau o mea'ai.

- Fa'aleleia le tulaga lelei ma le tumau.

A'o le'i fa'amama fa'amalosi, e mana'omia le su'esu'eina o le fa'aleagaina o luga o lo'o iai. O le malamalama i le ituaiga, le tele o le tufatufaga, ma le fa'avasegaga fa'aleaganu'u o mea fa'aleaga i luga o le fa'aele'ele'ele'ele e fa'amalieina ai le kemisi fa'amama ma le fa'aogaina o le malosi fa'ainisinia.

3. Fa'ata'ita'iga Fa'apitoa mo Su'esu'ega Fa'aleaga

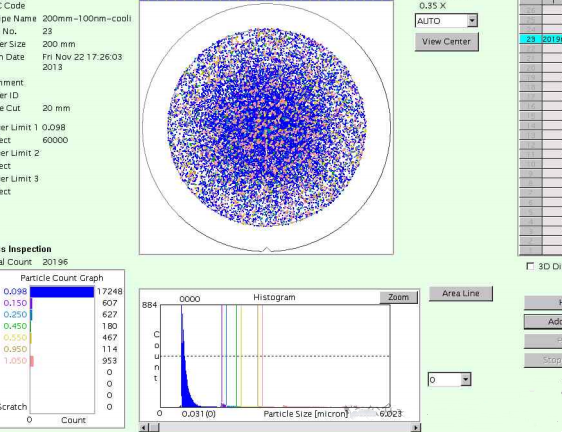

3.1 Su'esu'ega Fa'aele'ele i luga

- O fa'atauga fa'apitoa fa'apitoa e fa'aogaina le fa'ata'apeina o le laser po'o le va'aiga komepiuta e faitau, lapopoa, ma fa'afanua lapisi luga.

- O le malosi o le fa'asalalauina o le malamalama e fetaui lelei ma lapopo'a laiti e pei o le sefulu nanometers ma densities maualalo ifo i le 0.1 particles/cm².

- O le fa'avasegaina fa'atasi ma fa'ata'ita'iga fa'amautinoaina le fa'atuatuaina o meafaigaluega. O su'esu'ega a'o le'i fa'amama ma le mae'a ona fa'amama e fa'amaonia ai le lelei o le aveeseina, fa'aleleia le fa'agasologa o galuega.

3.2 Su'esu'ega Fa'afanua Elemental

- O metotia fa'apitoa e fa'aalia ai elemene elemene.

- X-ray Photoelectron Spectroscopy (XPS/ESCA): Su'esu'e tulaga kemikolo i luga o le eleele e ala i le fa'amumuina o le wafer i le X-ray ma le fuaina o le eletise.

- Glow Discharge Optical Emission Spectroscopy (GD-OES): Sputters ultra-manifinifi fa'asologa fa'asolosolo a'o su'esu'eina alaleo lafoa'i e iloa ai le loloto fa'alagolago i elemene elemene.

- O tapula'a o le su'esu'eina e o'o atu i vaega i le miliona (ppm), e ta'ita'ia ai le filifilia o kemisi sili ona lelei.

3.3 Su'esu'ega Fa'aleagaina o le Morphological

- Su'ega Electron Microscopy (SEM): Pu'eina ata maualuga e fa'aalia ai foliga o mea leaga ma fua fa'atatau, e fa'ailoa ai faiga fa'apipi'i (kemikolo vs. masini).

- Atomic Force Microscopy (AFM): Fa'afanua nanoscale topography e fa'atatauina le maualuga o vaega ma mea fa'ainisinia.

- Focused Ion Beam (FIB) Milling + Transmission Electron Microscopy (TEM): Tuuina atu vaaiga i totonu o le tanumia o mea leaga.

4. Metotia Fa'amama Fa'apitoa

A'o fa'amama lelei le fa'amama o le solvent, e mana'omia ni isi auala fa'aopoopo mo mea fa'aleaganu'u, toega u'amea, ma mea fa'aleagaina:

'

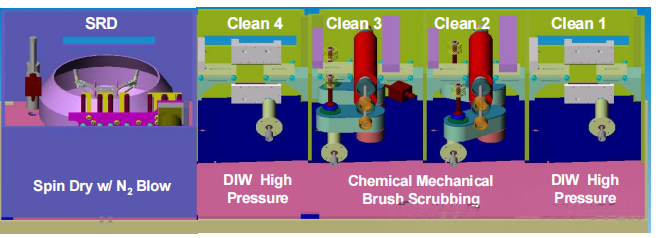

4.1 Fa'amamaina RCA

- Fausiaina e le RCA Laboratories, o lenei metotia e faʻaogaina ai se taʻele lua-taele e aveese ai mea leaga.

- SC-1 (Standard Clean-1): Ave'esea mea fa'a'ala'au fa'aleaga ma mea ninii e fa'aogaina ai le fa'afefiloi o le NH₄OH, H₂O₂, ma le H₂O (fa'ata'ita'iga, 1:1:5 ratio ile ~20°C). Fausia se mea manifinifi silicon dioxide.

- SC-2 (Standard Clean-2): Aveese le u'amea eleelea e fa'aaoga ai le HCl, H₂O₂, ma le H₂O (faataitaiga, 1:1:6 ratio ile ~80°C). E tu'u ai se fa'afefe.

- Fa'apaleni le mama ma le puipuiga o luga.

'

4.2 Fa'amamaina ole Osone

- Fa'atofuina i le vai fa'a'ona (O₃/H₂O).

- Fa'asa'o lelei ma aveese mea ola e aunoa ma le fa'aleagaina o le wafer, ma tu'u ai se mea fa'a'ona.

'

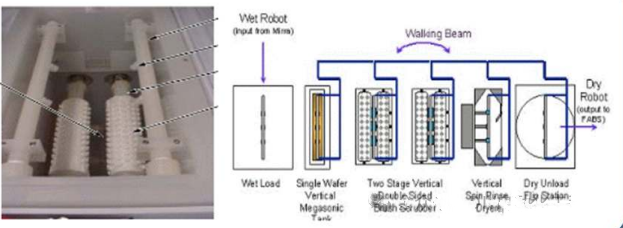

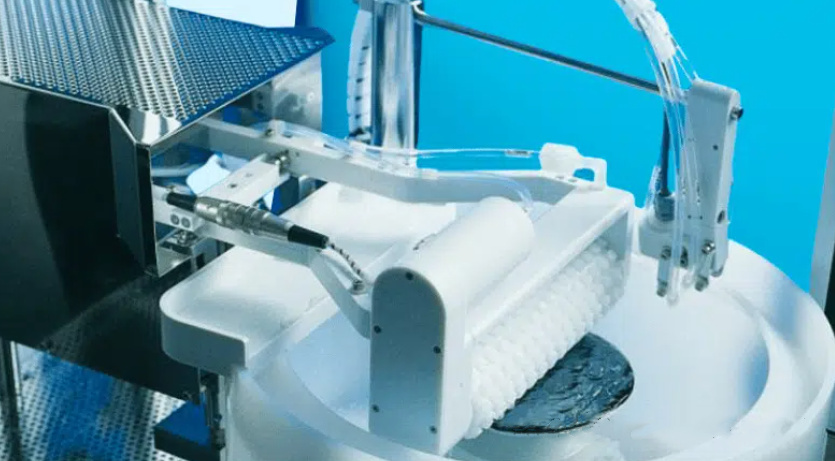

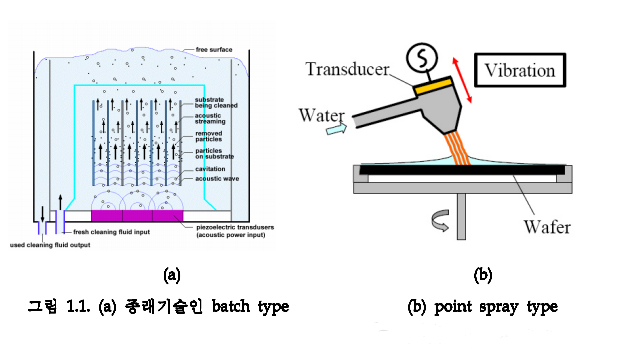

4.3 Fa'amamaina Megasonic'

- Fa'aaogāina ole malosi ole ultrasonic (e masani ole 750-900kHz) fa'atasi ma vaifofo fa'amama.

- Fa'atupu fa'a'a'a'a'a'a e fa'ate'a'ese mea leaga. Fa'asalaina geometries lavelave a'o fa'aitiitia le fa'aleagaina o fausaga ma'ale'ale.

4.4 Fa'amamaina Cryogenic

- Fa'ato'a fa'amalo fa'amalo i le vevela cryogenic, fa'apalapala pala.

- O le fufuluina mulimuli po'o le pulumu lemu e aveese ai mea'ai matala. Puipuia le toe fa'aleagaina ma fa'asalalau i luga.

- Fa'atosina vave, fa'amamago fa'atasi ai ma le fa'aaogaina o vaila'au.

Fa'ai'uga:

I le avea ai o se taʻutaʻua taʻutaʻua semiconductor solutions, XKH o loʻo faʻauluina e tekinolosi faʻafouga ma manaʻoga tagata faʻatau e tuʻuina atu se faʻauʻuga faʻanatura faʻanatura e aofia ai sapalai meafaigaluega maualuga, faʻapipiʻi wafer, ma le faʻamamaina saʻo. E le gata ina matou tu'uina atu masini semiconductor fa'avaomalo fa'avaomalo (fa'ata'ita'iga, masini lithography, etching system) fa'atasi ai ma fofo fa'apitoa ae fa'apea fo'i ma paionia fa'atautaiga tekonolosi—e aofia ai le fa'amamaina o le RCA, fa'amamāina o le osone, ma le fa'amama megasonic—ia fa'amautinoa le mama fa'aatomika mo le gaosiga o wafer, fa'asilisiliina lelei le gaosiga ma le lelei o le gaosiga. O le fa'aogaina o 'au e tali vave atu i le lotoifale ma feso'ota'iga au'aunaga atamai, matou te tu'uina atu le lagolago atoatoa e amata mai i le fa'apipi'iina o masini ma le fa'aogaina o le fa'agasologa i le tausiga fa'apitoa, fa'amalosia tagata fa'atau e fa'ato'ilaloina lu'itau fa'atekinisi ma aga'i atu i le sa'o maualuga ma le fa'atumauina semiconductor atina'e. Filifili i matou mo se faʻatasi-manumalo faʻatasi o tomai faʻapitoa ma tau pisinisi.

Taimi meli: Sep-02-2025