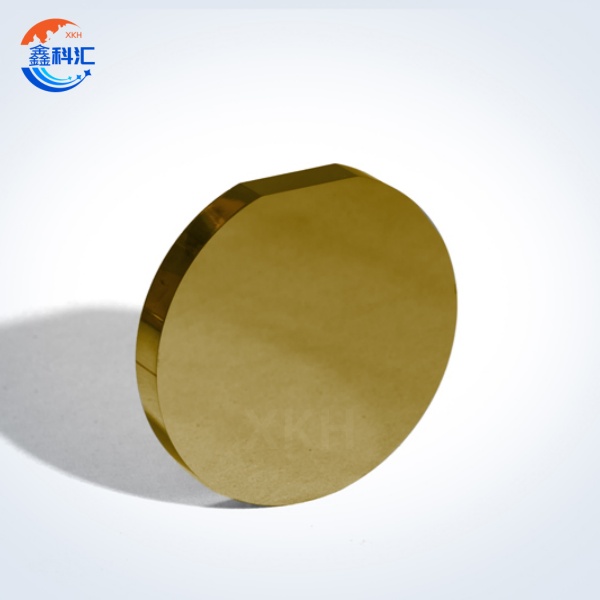

12 Inisi SiC substrate Diameter 300mm Mafiafia 750μm 4H-N Ituaiga e mafai ona fa'avasegaina

Fa'agata fa'atekinisi

| 12 inisi Silicon Carbide (SiC) Substrate Fa'amatalaga | |||||

| Vasega | ZeroMPD Gaosiga Vasega(Z Vasega) | Gaosiga Fa'ata'atia Vasega(P Vasega) | Fa'ailoga Tulaga (D Vasega) | ||

| Diamita | 3 0 0 mm~1305mm | ||||

| mafiafia | 4H-N | 750μm±15μm | 750μm±25μm | ||

| 4H-SI | 750μm±15μm | 750μm±25μm | |||

| Fa'asinomaga ole Wafer | Tu'u ese: 4.0° agai i le <1120 >±0.5° mo le 4H-N, I luga ole axis: <0001>±0.5° mo le 4H-SI | ||||

| Micropipe Density | 4H-N | ≤0.4cm-2 | ≤4cm-2 | ≤25cm-2 | |

| 4H-SI | ≤5cm-2 | ≤10cm-2 | ≤25cm-2 | ||

| Tete'e | 4H-N | 0.015~0.024 Ω·cm | 0.015~0.028 Ω·cm | ||

| 4H-SI | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |||

| Primary Flat Orientation | {10-10} ±5.0° | ||||

| Primary Flat Umi | 4H-N | N/A | |||

| 4H-SI | Notch | ||||

| Tuusaunoaga Tupito | 3 mm | ||||

| LTV/TTV/Bow/Warp | ≤5μm/≤15μm/≤35 μm/≤55 μm | ≤5μm/≤15μm/≤35 □ μm/≤55 □ μm | |||

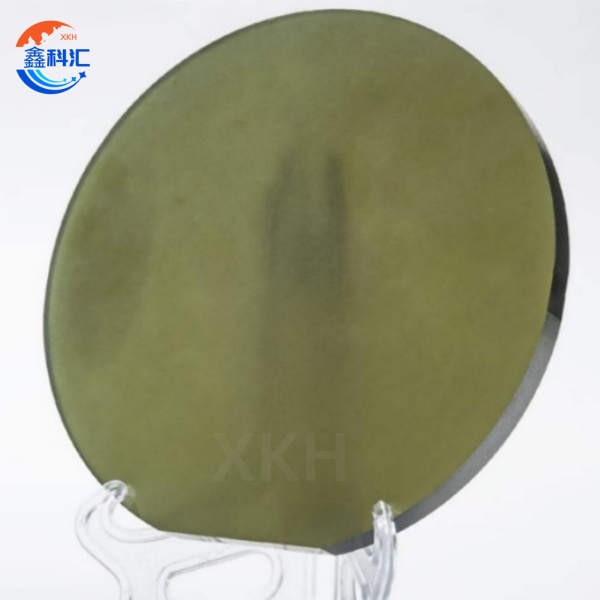

| Talatala | Polani Ra≤1 nm | ||||

| CMP Ra≤0.2 nm | Ra≤0.5 nm | ||||

| Ta'eta'e Tu'u I le Malamalama Maualuluga Papatusi Hex I Malamalama Maualuga Maualuga Polytype Areas I le Malamalama Maualuga Vaaiga Carbon Inclusions Susi Sili Sili I luga o le Malamalama Maualuga | Leai Vaega fa'aopoopo ≤0.05% Leai Vaega fa'aopoopo ≤0.05% Leai | Fa'aputu umi ≤ 20 mm, tasi umi≤2 mm Vaega fa'aopoopo ≤0.1% Vaega fa'aopoopo≤3% Vaega fa'aopoopo ≤3% Fa'aopoopo umi≤1×wafer diameter | |||

| Tipi Chips E Malamalama Malosi Maualuga | Leai se faatagaina ≥0.2mm lautele ma loloto | 7 faatagaina, ≤1 mm taitasi | |||

| (TSD) Fa'ase'e fa'avili fa'a filo | ≤500 cm-2 | N/A | |||

| (BPD) Fa'avae va'alele va'alele | ≤1000 cm-2 | N/A | |||

| Silicon Surface Contamination E le Malamalama Maualuga | Leai | ||||

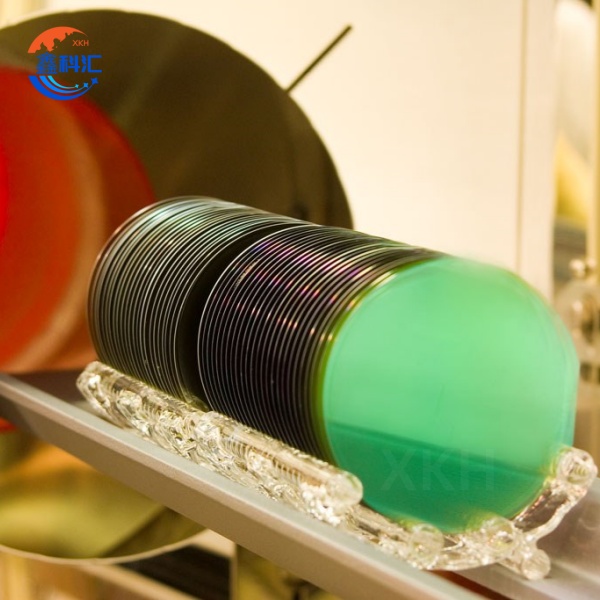

| afifiina | Tele-wafer kaseti po'o se atigi apa e tasi | ||||

| Fa'amatalaga: | |||||

| 1 Fa'agata fa'aletonu e fa'atatau i luga atoa o ga'o masi se'i vagana ai le pito e fa'ate'aina. 2E tatau ona siaki na'o mata Si. 3 O fa'amaumauga fa'aletonu e na'o le KOH wafers ua togitogia. | |||||

Vaega Autu

1. Gafatia Gafatia ma Tulaga Tau: O le tele o le gaosiga o le 12-inch SiC substrate (12-inch silicon carbide substrate) e faailogaina ai se vaitau fou i le gaosiga o le semiconductor. Ole aofa'i o tupe meataalo e maua mai i le wafer e tasi e o'o ile 2.25 taimi nai lo le 8-inisi substrates, fa'aoso sa'o le oso i le gaosiga lelei. O fa'amatalaga a tagata fa'atau e fa'ailoa mai ai o le fa'aaogaina o substrate 12-inisi ua fa'aitiitia ai le tau o le gaosiga o masini eletise i le 28%, ma fa'atupuina ai se tulaga fa'atauva'a fa'atauva'a i le maketi o lo'o finau malosi.

2. Tulaga Fa'aletino Fa'aletino: O le 12-inisi SiC substrate fa'atosina uma tulaga lelei o mea carbide silicon - o lona conductivity vevela e 3 taimi o le silicon, ae o lona malepelepe fanua malosi e oʻo atu i le 10 taimi o le silicon. O nei uiga e mafai ai e masini e faʻavae i luga o le 12-inisi substrates e faʻagaioi lelei i siosiomaga maualuga-vevela e sili atu i le 200 ° C, e faʻapitoa ai mo le manaʻomia o talosaga e pei o taʻavale eletise.

3.Surface Togafitiga Tekinolosi: Ua matou atiina ae se tala fou chemical polesina (CMP) faagasologa faapitoa mo 12-inisi SiC substrates, ausia atomic-level surface flatness (Ra<0.15nm). O lenei lavelave e foia ai le luitau i le lalolagi atoa o le tele-diameter silicon carbide wafer surface treatment, faʻamama faʻalavelave mo le maualuga o le epitaxial tuputupu aʻe.

4.Thermal Pulega Fa'atinoga: I fa'atinoga fa'atino, 12-inisi SiC substrates fa'aalia le mata'ina o le fa'amamaina o le vevela. O faʻamaumauga o suʻega o loʻo faʻaalia ai i lalo o le malosi tutusa, o masini e faʻaogaina ai le 12-inisi substrates e faʻaogaina i le vevela 40-50 ° C maualalo ifo nai lo masini faʻavae silicon, faʻateleina le ola tautua meafaigaluega.

Talosaga Autu

1.New Energy Vehicle Ecosystem: O le 12-inch SiC substrate (12-inch silicon carbide substrate) o loʻo faʻafouina le fausaga eletise eletise eletise. Mai luga o uta (OBC) i le faʻaogaina o le taʻavale autu ma le faʻaogaina o maa, o le faʻaleleia lelei o le faʻaleleia o mea e 12-inisi e faʻateleina ai le taʻavale i le 5-8%. O lipoti mai se kamupani taʻutaʻua taʻutaʻua o loʻo faʻaalia ai o le faʻaaogaina o a matou mea e 12-inisi e faʻaitiitia ai le malosi o le malosi i totonu o le latou faʻaogaina vave i le 62%.

2. Fa'afouina Malosiaga Vaega: I le photovoltaic power stations, inverters e fa'avae i luga o le 12-inisi SiC substrates e le gata o lo'o fa'aalia ai mea laiti laiti ae fa'apea fo'i ona ausia le fa'aliliuga lelei e sili atu i le 99%. Aemaise lava i fa'asologa o fa'asologa fa'asoa, o lenei tulaga maualuga e fa'aliliuina i sefe fa'aletausaga o le selau afe o yuan i le pa'u eletise mo le au fa'afoe.

3.Industrial Automation: Fa'aliliuga fa'atele e fa'aaogaina 12-inisi substrates fa'aalia le lelei tele o fa'atinoga i robots fale gaosi oloa, masini masini CNC, ma isi masini. O latou uiga fa'afeso'ota'i maualuga e fa'aleleia ai le saoasaoa o le tali atu i le afi i le 30% a'o fa'aitiitia le fa'alavelave fa'aeletise i le tasi vaetolu o fofo masani.

4. Consumer Electronics Innovation: Ua amata ona faʻaaogaina e le tupulaga e sosoo ai le telefoni feaveaʻi o tekonolosi faʻapipiʻi 12-inisi SiC substrates. O loʻo faʻamoemoeina o oloa faʻapipiʻiina i luga aʻe o le 65W o le a suia atoa i vaifofo carbide silicon, faʻatasi ai ma substrates 12-inisi o loʻo faʻaalia e avea ma filifiliga sili ona lelei tau-faatinoga.

XKH Au'aunaga Fa'apitoa mo le 12-inisi SiC Substrate

Ina ia ausia manaoga faapitoa mo 12-inisi SiC substrates (12-inisi silicon carbide substrates), XKH ofo atu auaunaga lagolago atoatoa:

1.Thickness Customization:

Matou te tuʻuina atu 12-inisi substrates i faʻamatalaga mafiafia eseese e aofia ai le 725μm e faʻafetaui ai manaʻoga eseese.

2. Doping fa'atonuga:

O la matou gaosiga e lagolagoina le tele o ituaiga conductivity e aofia ai le n-ituaiga ma le p-ituaiga substrates, faʻatasi ai ma le faʻatonuina o le resistivity i le va o le 0.01-0.02Ω·cm.

3. Au'aunaga Su'ega:

Fa'atasi ai ma masini su'ega wafer-level atoatoa, matou te tu'uina atu lipoti atoa o asiasiga.

XKH malamalama o tagata fa'atau ta'itasi e iai mana'oga tulaga ese mo 12-inisi SiC substrates. O le mea lea matou te ofoina atu faʻataʻitaʻiga felagolagomai pisinisi fetuutuunai e tuʻuina atu fofo sili ona tauva, pe mo:

· Fa'ata'ita'iga R&D

· Volume gaosiga fa'atau

O a matou 'au'aunaga fa'apitoa e fa'amautinoa e mafai ona matou fa'amalieina ou mana'oga fa'apitoa fa'apitoa ma gaosiga mo 12-inisi SiC substrates.