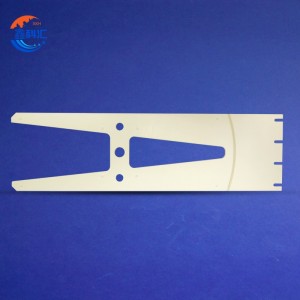

Fa'ato'a Fa'ai'uga Fa'ai'uga Alumina Ceramic (Alima Tu'u) mo Semiconductor ma Fale mama.

Auiliili Ata

Folasaga o oloa

O le Alumina Ceramic End Effector, e taʻua foi o se lima tui poʻo lima lima lima lima, o se mea e faʻatautaia ai le saʻo maualuga ua fuafuaina mo faiga faʻapitoa i semiconductor, photovoltaic, faʻaaliga panel, ma siosiomaga falesuesue maualuga-mama. E fa'ainisinia e tu'uina atu ai le fa'amautu fa'apitoa o le vevela, malosi fa'ainisinia, ma le tete'e atu i vaila'au, ofoina mama, fa'atuatuaina, ma le saogalemu o felauaiga o mea ma'ale'ale e pei o fa'ama'i kasa, mea tioata, ma vaega fa'aeletoroni.

I le avea ai ma se ituaiga o robotic end effector, o lenei vaega sima o le fesoʻotaʻiga mulimuli i le va o le masini masini ma le mea faigaluega. E iai sona sao taua i le sa'o lelei o le fesiita'iga, fa'aogaina, utaina/la'uina, ma le fa'atulagaina o galuega i potu mama ma vacuum si'osi'omaga.

Va'aiga Lautele - Alumina Ceramic (Al₂O₃)

Alumina ceramic ose mea fa'atekinisi fa'apitoa fa'atekinisi e sili ona mautu ma fa'ainisinia e iloa ona o lona lelei fa'ainisinia ma eletise. O le maualuga-mama (≥ 99.5%) alumina o loʻo faʻaaogaina i nei mea faʻaiʻuga faʻamautinoa:

-

Malosi maualuga (Mohs 9): Na'o lona lua i taimane, alumina e maua ai le malosi o le ofuina.

-

Mafai maualuga-vevela: Fa'atumauina le fa'amaoni o le fa'atulagaga i luga a'e o le 1600°C.

-

Fa'aleti vaila'au: Tete'e i acids, alkalis, solvents, ma siosiomaga etching plasma.

-

Insulation eletise: Faatasi ai ma le malosi dielectric maualuga ma maualalo dielectric gau.

-

Fa'alauteleina le vevela maualalo: Fa'amautinoa le mautu o itu i totonu o si'osi'omaga uila vevela.

-

Fa'atupuina o vaega laiti: Taua mo le fetaui lelei potu mama (Vaega 10 i le Vasega 1000).

O nei vaega e fa'apena le alumina ceramic e fetaui lelei mo galuega fa'a-misiona i totonu o alamanuia fa'aleagaina.

Talosaga Fa'atino

O le alumina ceramic end effector o loʻo faʻaaogaina lautele i faiga faʻatekonolosi faʻatekonolosi, aemaise lava pe a faʻapuupuu mea uʻamea masani poʻo palasitika ona o le faʻalauteleina o le vevela, faʻaleagaina, poʻo faʻafitauli pala. O fanua talosaga autu e aofia ai:

- Semiconductor wafer fesiitaiga

- Faiga faʻapipiʻi ma le laʻuina o ata

- O lo'o fa'aogaina le mea'ai tioata i laina OLED ma LCD

- Fa'aliliuina wafer silikoni tioata i le gaosiga o le la

- Otometi su'esu'ega opitika po'o microelectronic

- Fa'ata'ita'iga felauaiga ile su'esu'ega po'o le biomedical labs

- Vacuum si'osi'omaga faiga otometi

O lona gafatia e fa'atino e aunoa ma le fa'aofiina o ni vaega po'o le tau fa'atete'e e mana'omia ai mo le fa'aogaina sa'o o le robotic i le masini mama.

Fua Fa'ailoga & Fa'asinomaga

E fa'ainisinia uma mea fa'ai'u sima ina ia fetaui ma se lima robotic fa'apitoa po'o le fa'aogaina o masini. Matou te lagolagoina le faʻatulagaina atoa e faʻavae i luga o:

-

Fegalegaleai le tele o le wafer: 2", 4", 6", 8", 12" ma isi

-

Slot geometry ma avanoa: Fa'afeiloa'i le u'u pito, lagolago pito i tua, po'o mamanu fa'ama'i

-

Suction ports: Pu'u gaogao tu'ufa'atasia po'o alavai mo le tagofiaina e le fa'afeso'ota'i

-

Fa'atonuga fa'apipi'i: Pu, filo, avanoa e fa'aoga i le lau'au'au'au'amea pito i'u a lau robot

-

Togafitiga luga: Faila, lape, po'o le mae'a lelei (Ra <0.2 µm avanoa)

-

Puipuiga pito: Tu'u lapotopoto po'o le fa'a'au'au e 'alofia ai le fa'aleagaina

I le fa'aogaina o ata CAD po'o fa'ata'ita'iga 3D e tu'uina mai e tagata fa'atau, e mafai e a tatou inisinia ona fa'amalieina lima tui ta'itasi mo le mamafa, malosi, ma le mama.

Tulaga lelei ole Ceramic End Effectors

| Fa'aaliga | Faamanuiaga |

|---|---|

| Maualuluga Fa'ainisinia | Fa'atumauina le sa'o sa'o i lalo ole malosi ole utaina |

| Lelei Fa'atino Fa'avevela | Fa'atino fa'atuatuaina i si'osi'omaga maualuga po'o si'osi'omaga plasma |

| Fa'aleagaina uamea e leai | Leai se lamatiaga o le faʻaleagaina o ion i le faʻaogaina o semiconductor ogaoga |

| Lau'ele'ele Fe'ese'ese maualalo | Fa'aiti'itia le masi'i i luga o mea fa'apipi'i po'o ipu tioata |

| Anti-Static ma Non-Maneta | E le tosina mai le pefu pe afaina ai vaega maneta |

| Umi Auaunaga Ola | E sili atu le tete'e i le ofuina i ta'amilosaga fa'aautomatika maualuga fa'asolosolo |

| Ultra-Mama Fegalegaleaiga | E talafeagai mo potu mama ISO 14644 (Vaega 100 ma lalo) |

Pe a fa'atusatusa i lima palasitika po'o alumini, alumina ceramic e maua ai le fa'aleleia atili o vaila'au ma fa'amautu fa'aletino ma fa'aitiitia le tausiga.

| Meatotino | Lima uamea | Lima palasitika | Alumu Ceramic Arm |

|---|---|---|---|

| Malosi | feololo | Maulalo | Maualuga Maualuga (Mohs 9) |

| Fa'amaumau vevela | ≤ 500°C | ≤ 150°C | ≥ 1600°C |

| Tete'e vaila'au | feololo | Mativa | Lelei |

| Talafeagai Potu Mama | Alafua | Maulalo | Maualuga Maualuga |

| La'ei Tetee | Alafua | Maulalo | Mata'ina |

| Malosiaga Dielectric | Maulalo | Alafua | Maualuga |

| Sa'o Fa'aagaienisi | Fa'atapula'a | feololo | Maualuluga (±0.01mm e mafai) |

Fa'amatalaga Fa'apitoa

| Parameter | Taua |

|---|---|

| Meafaitino | Alumina maualuga-mama (≥ 99.5%) |

| Galulue Vevela | E oo atu i le 1600°C |

| Fa'asaa o luga | Ra ≤ 0.2 µm (filifiliga) |

| Laise Wafer talafeagai | 2" i le 12" po'o aga masani |

| Fa'apalepale mafolafola | ±0.01 mm (fa'atatau ile talosaga) |

| Lagolago Suction Vacuum | Auala e filifili, fa'avasegaina |

| Filifiliga Fa'amau | Fa'amau, fa'au'u, pu fa'alava |

Fesili e Fai soo (FAQ)

Q1: E mafai ona tuʻufaʻatasia le faʻamaʻi faʻaiʻuga i faiga faʻaogaina o loʻo iai?

A1:Ioe. Matou te lagolagoina aganu'u fa'avae i luga o lau atina'e robotic. E mafai ona e auina mai ia i matou se ata CAD poʻo le fua o le flange mo le faʻaogaina saʻo.

Q2: E faigofie ona gau lima sima a'o fa'aoga?

A2:E ui ina ma'ale'ale le sima ona o le natura, o matou mamanu e fa'aogaina le geometry sili ona lelei e fa'aitiitia ai le mamafa. I lalo o tulaga faʻaoga tatau, latou te maua ai le umi o le auaunaga nai lo le uʻamea poʻo le palasitika.

Q3: E mafai ona faʻaogaina lenei mea i totonu ole vacuum ultra-high poʻo potu etching plasma?

A3:Ioe. O le alumini ceramic e le mafai ona alu ese, faʻamautu vevela, ma e teteʻe i le pala-e fetaui lelei mo le gaogao maualuga, kasa faʻafefe, poʻo siʻosiʻomaga plasma.

Q4: E faʻafefea ona faʻamamaina pe tausia nei vaega?

A4:E mafai ona fa'amamāina e fa'aaoga ai le vai DI, ava malosi, po'o vaimea e fetaui ma potu mama. Leai se tausiga fa'apitoa e mana'omia ona o lo latou mautu o vaila'au ma luga ole inert.

Faatatau ia tatou

XKH faʻapitoa i atinaʻe tekonolosi, gaosiga, ma faʻatau atu o tioata faʻapitoa faʻapitoa ma mea tioata fou. O a matou oloa e tautuaina mea fa'aeletonika mata, mea fa'atau eletise, ma le militeri. Matou te ofoina atu vaega opitika Safaira, ufiufi tioata telefoni feʻaveaʻi, Ceramics, LT, Silicon Carbide SIC, Quartz, ma semiconductor wafers tioata. Faatasi ai ma le tomai faʻapitoa ma meafaigaluega faʻapitoa, matou te sili atu i le gaosiga o oloa e le masani ai, faʻamoemoe e avea ma taʻutaʻua optoelectronic mea faʻatekonolosi atinaʻe.