Meafaigaluega Semiconductor Laser Lift-Off Revolutionize Ingot Thinning

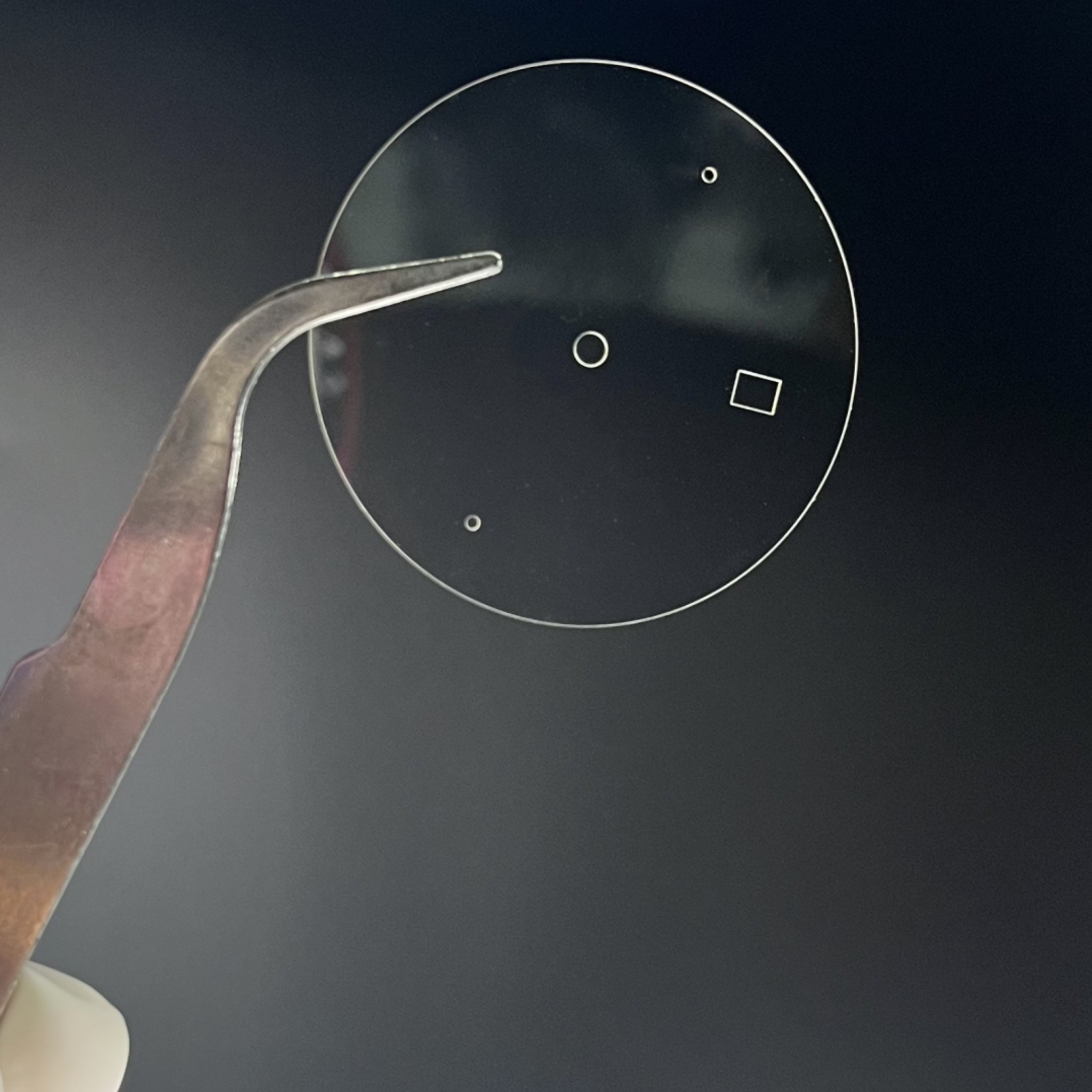

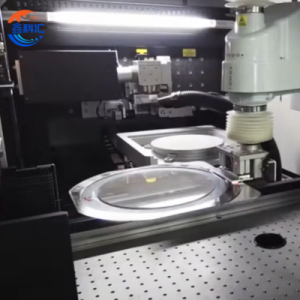

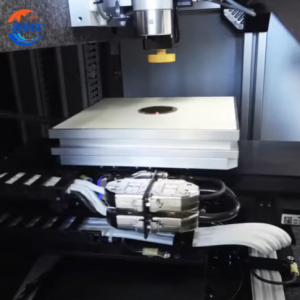

Auiliili Ata

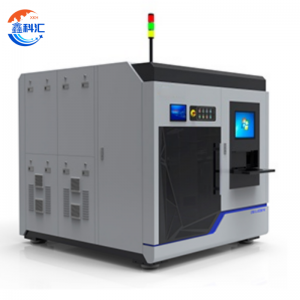

Oloa Fa'atomuaga o Meafaigaluega Semiconductor Laser Lift-Off

Ole Semiconductor Laser Lift-Off Equipment ose fofo fa'apitoa fa'apitoa e fa'ainisinia mo le fa'amama sa'o ma le le fa'afeso'ota'i o mea fa'apipi'i semiconductor e ala ile laser-induced techniques lift-off. O lenei faiga alualu i luma o loʻo i ai se sao taua i faiga faʻaonaponei semiconductor wafering, aemaise lava i le fausiaina o faʻamaʻi manifinifi ultra mo eletise eletise maualuga, LED, ma masini RF. E ala i le fa'atagaina o le tu'ueseeseina o mea manifinifi mai le tele o ingots po'o le foa'i substrates, Semiconductor Laser Lift-Off Equipment revolutionizes ingot thinning e ala i le aveesea o masini iliili, olo, ma vailaau etching laasaga.

O le fa'amama fa'aleaganu'u masani o mea semiconductor, e pei o le gallium nitride (GaN), silicon carbide (SiC), ma le safaira, e masani ona galue malosi, maumau, ma faigofie i microcracks poʻo faʻaleagaina luga. I se fa'afeagai, Semiconductor Laser Lift-Off Equipment e ofoina atu se mea e le fa'aleagaina, sa'o lelei e fa'aitiitia ai mea fa'aletonu ma fa'alavelave i luga ae fa'ateleina le gaosiga. E lagolagoina le tele o ituaiga tioata ma mea faʻapipiʻi ma e mafai ona tuʻufaʻatasia faʻatasi i luma poʻo le ogatotonu o laina gaosiga semiconductor.

Fa'atasi ai ma fa'amautu umi galu leisa, fa'aogaina fa'aoga fa'aoga, ma vacuum-compatible wafer chucks, o nei meafaigaluega e matua fetaui lelei lava mo le slicing ingot, lamella creation, ma ultra-thin film detachment mo fausaga masini tūsaʻo po o heteroepitaxial layer transfer.

Parameter o Meafaigaluega Semiconductor Laser Lift-Off

| Umi ole galu | IR/SHG/THG/FHG |

|---|---|

| Pulse Lautele | Nanosecond, Picosecond, Femtosecond |

| Optical System | Fa'atonu faiga fa'apitoa po'o le Galvano-optical system |

| XY Vaega | 500 mm × 500 mm |

| Tulaga Fa'agaioiga | 160 mm |

| Saosaoa o Gaoioiga | Max 1,000 mm/sec |

| Toe fai | ±1 μm pe itiiti |

| Tulaga Sa'o atoatoa: | ±5 μm pe itiiti |

| Tele ole Wafer | 2–6 inisi pe fa'apitoa |

| Pulea | Windows 10,11 ma le PLC |

| Malosiaga Sapalai Malosi | AC 200 V ± 20 V, Vaega e tasi, 50/60 kHz |

| Fua i fafo | 2400 mm (W) × 1700 mm (D) × 2000 mm (H) |

| mamafa | 1,000 kilokalama |

Fa'avae Galuega ole Semiconductor Laser Lift-Off Mequipment

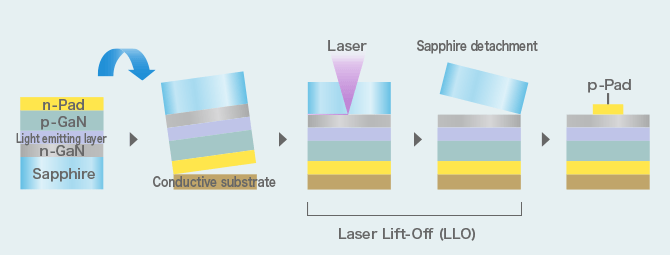

O le masini autu o le Semiconductor Laser Lift-Off Equipment e faʻalagolago i le filifilia o le photothermal decomposition poʻo le ablation i le va o le donor ingot ma le epitaxial poʻo le faʻapipiʻiina. O se leisa UV malosi-maualuga (e masani lava KrF i le 248 nm po'o le malosi o le UV lasers e uiga i le 355 nm) e taula'i atu i se mea fa'ameaalofa manino po'o semi-manino, lea e fa'amalieina ai le malosi i se loloto fa'atulagaina.

O lenei fa'aogaina o le malosi fa'apitonu'u e fa'atupuina ai se vaega o le kasa maualuga po'o le fa'alauteleina o le vevela i le fa'aoga, lea e amata ai le fa'amama mama o le fafie pito i luga po'o le masini masini mai le fa'avae ingot. O le fa'agasologa o lo'o fa'alogo lelei e ala i le fetu'una'iga o fa'amaufa'ailoga e pei o le lautele o le pulupulu, fa'alogo leisa, le saoasaoa o su'esu'ega, ma le loloto o le fa'aitu o le z-axis. O le taunuuga o se fasi tipi e sili ona manifinifi—e masani lava ile 10 i le 50 µm—e vavae ese mai le ingot matua e aunoa ma le abrasione masini.

Ole auala lea ole fa'aeseese ole leisa mo le fa'amamaina o ingot e 'alofia ai le gau ma le fa'aleagaina o luga e feso'ota'i ma le va'aiga uaea taimane po'o le fa'aogaina o masini. E fa'asaoina ai fo'i le fa'amaoni tioata ma fa'aitiitia ai mana'oga fa'apolopolo i lalo, ma avea ai le Semiconductor Laser Lift-Off Equipment o se meafaigaluega e suia ai ta'aloga mo le gaosiga o le ga'o o lo'o soso'o mai.

Fa'aogaina o Meafaigaluega Semiconductor Laser Lift-Off

Semiconductor Laser Lift-Off Equipment e maua ai le fa'aogaina lautele i le fa'amama fa'amama i luga o le tele o mea fa'apitoa ma ituaiga masini, e aofia ai:

-

GaN ma GaAs Ingot Thinning mo masini eletise

Fa'aagaioia le faia o mea mama manifinifi mo le maualuga-lelei, maualalo-tetesi transistors mana ma diodes.

-

SiC Substrate Reclamation ma Lamella Separation

Fa'ataga le si'isi'i i luga ole fua fa'asolo mai le tele o mea fa'apipi'i SiC mo fausaga masini fa'atutusa ma toe fa'aoga masi.

-

LED Wafer Slicing

Fa'afaigofie ona si'i ese 'ese'esega o le GaN mai safaira mafiafia e maua ai mea e sili ona manifinifi o le LED.

-

RF ma masini microwave

Lagolagoina ultra-thin high-electron-mobility transistor (HEMT) fausaga e manaʻomia ile 5G ma le radar system.

-

Epitaxial Layer Transfer

Tu'u ese sa'o le epitaxial layers mai mea tioata mo le toe fa'aoga po'o le tu'ufa'atasia i totonu o fa'ameamea.

-

Tifi Manifinifi Solar Cells ma Photovoltaics

Fa'aaogā e tu'u'ese'ese ai fa'afu'afu manifinifi mo sela fe'avea'i po'o le maualuga o le la.

I totonu o nei vaega ta'itasi, Semiconductor Laser Lift-Off Equipment e maua ai le fa'atonuga le fa'atusaina i luga o le mafiafia tutusa, tulaga lelei o luga, ma le fa'amaoni o le laulau.

Tulaga lelei ole Ingot Thinning Laser-Fa'avae

-

Zero-Kerf Material Loss

Pe a fa'atusatusa i metotia fa'amea masani, o le fa'agasologa o le laser e maua ai le toeitiiti 100% le fa'aogaina o meafaitino.

-

Fa'aitiitiga Fa'atiga ma Fa'a'au

E le fa'afeso'ota'i le si'itia e fa'ate'aina ai le ga'o fa'ainisinia, fa'aitiitia le fa'afana o le aufana ma le fa'avaeina o le microcrack.

-

Fa'asaoina Tulaga Lelei

E le mana'omia le fa'amama po'o le fa'aiila i le tele o tulaga, aua e fa'asaoina e le laser le fa'amaoni i luga.

-

Maualuluga Auala ma Otometi Sauni

Mafai ona fa'agaoioi le fiaselau o mea'ai i le sifi fa'atasi ma le fa'a'oto'otoina o uta/la'u 'ese.

-

Fetuuna'i i Mea e Tele

E fetaui ma GaN, SiC, safaira, GaAs, ma mea fou III-V.

-

Siosiomaga Saogalemu

Fa'aiti'itia le fa'aogaina o mea fa'ama'i ma vaila'au malosi e masani ai i faiga fa'ama'i fa'avae e fa'avae slurry.

-

Toe Fa'aogaina o le eleele

E mafai ona toe fa'aaogaina mea'ai foa'i mo le tele o ta'amilosaga si'itia, e matua fa'aitiitia ai tau o meafaitino.

Fesili e Fai soo (FAQ) o Meafaigaluega Semiconductor Laser Lift-Off

-

Q1: O le a le mafiafia e mafai e le Semiconductor Laser Lift-Off Equipment ona ausia mo fasi pepa?

A1:O le mafiafia o fasi tipi e amata mai i le 10 µm i le 100 µm fa'atatau ile meafaitino ma le fa'atulagaina.Q2: E mafai ona faʻaogaina nei meafaigaluega i mea manifinifi e faia i mea faʻapitoa e pei o SiC?

A2:Ioe. E ala i le fa'alogoina o le umi o le galu leisa ma le fa'amaninoina o fa'ainisinia fa'aoga (fa'ata'ita'iga, mea fa'apipi'i taulaga), e o'o lava i mea fa'apitoa e mafai ona fa'agaioia.Q3: E fa'afefea ona fa'aogaina le mea fa'ameaalofa a'o le'i si'itia le laser?

A3:O lo'o fa'aogaina e le faiga fa'atonuga fa'atatau ile va'aiga i lalo ole micron fa'atasi ai ma fa'amatalaga mai fa'ailoga fa'amaoni ma su'esu'ega i luga ole ata.Q4: O le a le taimi faʻamoemoeina o le taamilosaga mo le tasi leisa e faʻaaogaina le faʻaaogaina?

A4:Fa'alagolago i le lapoa ma le mafiafia, o ta'amilosaga masani e umi mai le 2 i le 10 minute.Q5: E manaʻomia e le faagasologa se siosiomaga potu mama?

A5:E ui ina le fa'atulafonoina, e fautuaina le tu'ufa'atasia o potu mama e fa'atumauina ai le mama o mea'ai ma fua mai masini i le taimi o fa'agaioiga maualuga.

Faatatau ia tatou

XKH faʻapitoa i atinaʻe tekonolosi, gaosiga, ma faʻatau atu o tioata faʻapitoa faʻapitoa ma mea tioata fou. O a matou oloa e tautuaina mea fa'aeletonika mata, mea fa'atau eletise, ma le militeri. Matou te ofoina atu vaega opitika Safaira, ufiufi tioata telefoni feʻaveaʻi, Ceramics, LT, Silicon Carbide SIC, Quartz, ma semiconductor wafers tioata. Faatasi ai ma le tomai faʻapitoa ma meafaigaluega faʻapitoa, matou te sili atu i le gaosiga o oloa e le masani ai, faʻamoemoe e avea ma taʻutaʻua optoelectronic mea faʻatekonolosi atinaʻe.