SiC Ceramic Tray mo Wafer Carrier ma Tete'e Maualuluga

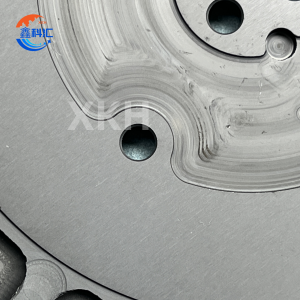

Silicon Carbide Ceramic Tray (SiC Tray)

O se vaega sima maualuga e faʻavae i luga o mea faʻapipiʻi carbide (SiC), faʻainisinia mo faʻaoga faʻapisinisi faʻapitoa e pei o le gaosiga o le semiconductor ma le gaosiga o le LED. O ana galuega autu e aofia ai le avea o se vaʻa wafer, etching process platform, poʻo le maualuga o le vevela o le faʻagasologa o le lagolago, le faʻaogaina o le faʻaogaina o le vevela, maualuga le vevela, ma le mautu o vailaʻau e faʻamautinoa ai le tutusa o le faagasologa ma fua o oloa.

Vaega Autu

1. Fa'atinoga Fa'avela

- Maualuluga Fa'avevela: 140–300 W/m·K, e sili mamao atu i le kalafi fa'aleaganu'u (85 W/m·K), e mafai ai ona vave fa'a'ave'esea le vevela ma fa'aitiitia ai le mamafa o le vevela.

- Fa'ateleina Fa'aalili Maalalo: 4.0×10⁻⁶/℃ (25–1000 ℃), fa'afetaui lelei le kasa (2.6×10⁻⁶/℃), fa'aitiitia le fa'aleagaina o le vevela.

2. Meatotino Fa'ainisinia

- Malosi Maualuga: Malosi faʻamalosi ≥320 MPa (20 ℃), faʻasaga i le faʻamalosi ma le aʻafiaga.

- Maualuluga Malosi: Mohs maaa 9.5, lona lua i taimane, e ofoina atu le maualuga o le ofuina.

3. Mauaina o vailaau

- Tete'e o le pala: Tete'e i acids malosi (fa'ata'ita'iga, HF, H₂SO₄), talafeagai mo siosiomaga faiga etching.

- Non-Magnetic: Fa'alavelave fa'amaneta <1×10⁻⁶ emu/g, aloese mai le fa'alavelave i meafaigāluega sa'o.

4. Fa'apalepale Si'osi'omaga Mata'utia

- Maualuluga-maualuga Malosi: umi-umi faagaioia vevela e oo atu i le 1600-1900℃; teteʻe pupuu e oʻo atu i le 2200 ℃ (siosiomaga leai se okesene).

- Tete'e Te'i vevela: Tatalia suiga fa'afuase'i o le vevela (ΔT>1000℃) e aunoa ma le ta'e.

Talosaga

| Talosaga Field | Tulaga Fa'apitoa | Taua fa'ainisinia |

| Gaosi semiconductor | Vafer etching (ICP), mea manifinifi-tifiti fa'apipi'i (MOCVD), CMP polesi | O le maualuga o le vevela e mautinoa ai le tutusa o le vevela; fa'alauteleina vevela maualalo e fa'aitiitia ai le warpage. |

| gaosiga o le LED | Epitaxial tuputupu ae (eg, GaN), wafer dicing, afifiina | Taofi le tele o ituaiga faaletonu, faʻaleleia le faʻamalamalamaina o le LED ma le umi o le ola. |

| Alamanuia Photovoltaic | Ogaumu sintering Silicon wafer, lagolago meafaigaluega PECVD | O le maualuga o le vevela ma le fa'ate'ia o le vevela e fa'alautele ai le ola o meafaigaluega. |

| Laser & Optis | Su'ega fa'amalieina leisa maualuga, lagolago fa'aogaina | O le maualuga o le vevela e mafai ai ona faʻafefe vave le vevela, faʻamautu vaega opitika. |

| Meafaigaluega su'esu'e | TGA/DSC fa'ata'ita'iga o lo'o umia | E maualalo le malosi o le vevela ma le tali vave o le vevela fa'aleleia le sa'o o fua. |

Tulaga lelei

- Aofa'i Fa'atinoga: O le fa'avevela vevela, malosi, ma le fa'a'ele'ele e sili mamao atu nai lo le alumina ma le silicon nitride ceramics, fa'afetaui mana'oga ogaoga fa'atino.

- Fuafuaga Mamafa: Malosi o le 3.1–3.2 g/cm³ (40% o le uamea), faʻaitiitia le mamafa o le uta ma faʻaleleia le saʻo o le gaioiga.

- Umi ma Faʻatuatuaina: O le ola tautua e sili atu i le 5 tausaga i le 1600 ℃, faʻaitiitia le taimi faʻaletonu ma faʻaititia le tau o galuega ile 30%.

- Fa'asinomaga: Lagolagoina fa'ata'ita'i lavelave (fa'ata'ita'iga, ipu suction porous, fata fa'apipi'i tele) fa'atasi ma mea sese <15 μm mo fa'aoga sa'o.

Fa'amatalaga Fa'apitoa

| Vaega Parameter | Fa'ailoga |

| Meatotino Faaletino | |

| Malosi | ≥3.10 g/cm³ |

| Malosi Fa'afilifili (20℃) | 320–410 MPa |

| Amioga vevela (20℃) | 140–300 W/(m·K) |

| Fa'ateleina Fa'avela (25–1000℃) | 4.0×10⁻⁶/℃ |

| Meatotino Kemisi | |

| Tete'e Asi (HF/H₂SO₄) | Leai se pala pe a uma le 24h faatofu |

| Fa'asa'o ole Masini | |

| Mafolafola | ≤15 μm (300×300 mm) |

| Talatala o le Lau'ele'ele (Ra) | ≤0.4 μm |

Au'aunaga a le XKH

O lo'o tu'uina atu e le XKH ni fofo fa'apisinisi fa'apitoa e fa'atatau i le atina'eina o aganu'u, fa'ama'i sa'o lelei, ma le fa'atonuga lelei. Mo le atinaʻeina faʻale-aganuʻu, e ofoina atu le maualuga-mama (> 99.999%) ma porous (30-50% porosity) fofo meafaitino, faʻatasi ma le 3D faʻataʻitaʻiga ma faʻataʻitaʻiga e faʻamalieina ai geometries lavelave mo talosaga e pei o semiconductor ma aerospace. O le fa'aogaina o le sa'o e mulimulita'i i se fa'agasologa fa'afaigofie: fa'aogaina o le pa'u → isostatic/mago fa'amama → 2200°C sintering → CNC/tamanino olo → su'esu'ega, fa'amautinoa le fa'aiila o le nanometer ma le ±0.01 mm le fa'apalepale. Fa'atonuga lelei e aofia ai fa'ata'ita'iga atoa (XRD tu'ufa'atasi, SEM microstructure, 3-point bending) ma lagolago fa'atekinisi (fa'atonuga fa'agasologa, 24/7 fa'atalanoaga, 48-itula fa'ata'ita'iga fa'ata'ita'iga), tu'uina atu fa'atuatuaina, maualuga fa'atinoga mo mana'oga fa'apisinisi.

Fesili e Fai soo (FAQ)

1. F: O a pisinisi e faʻaaogaina fata sima carbide silicon?

A: Fa'aaoga lautele i le gaosiga o le semiconductor (wafer handling), malosi sola (PECVD process), meafaigaluega fa'afoma'i (MRI component), ma le aerospace (vaega vevela) ona o le malosi o le vevela ma le mautu o vaila'au.

2. F: E fa'afefea ona sili atu le silicon carbide fata fata tioata?

A: Tete'e fa'ate'ia maualuga (e o'o atu i le 1800°C vs. 1100°C o le quartz), fa'alavelave fa'amaneta e leai, ma le umi o le ola (5+ tausaga vs. 6-12 masina o le quartz).

3. F: E mafai e fata carbide silikon ona taulimaina siosiomaga acidic?

A: Ioe. E tetee atu i le HF, H2SO4, ma le NaOH i le <0.01mm corrosion/tausaga, ma avea ai ma mea lelei mo le fa'a'isi'i vaila'au ma fa'amama mama.

4. F: E fetaui fata fa'ameamea kasa ma masini?

A: Ioe. Fuafuaina mo le vacuum pickup ma le robotic handling, faatasi ai ma le mafolafola o luga <0.01mm e puipuia ai le faaleagaina o ni vaega i totonu o fale masini.

5. F: O le a le fa'atusatusaga o tau ma mea masani?

A: Tau maualuga maualuga (3-5x quartz) ae 30-50% maualalo le TCO ona o le umi o le ola, faʻaitiitia le taimi e faʻaalu ai, ma le faʻasaoina o le malosi mai le maualuga o le vevela.