Silicon Carbide Ceramic Fork Arm/Lima

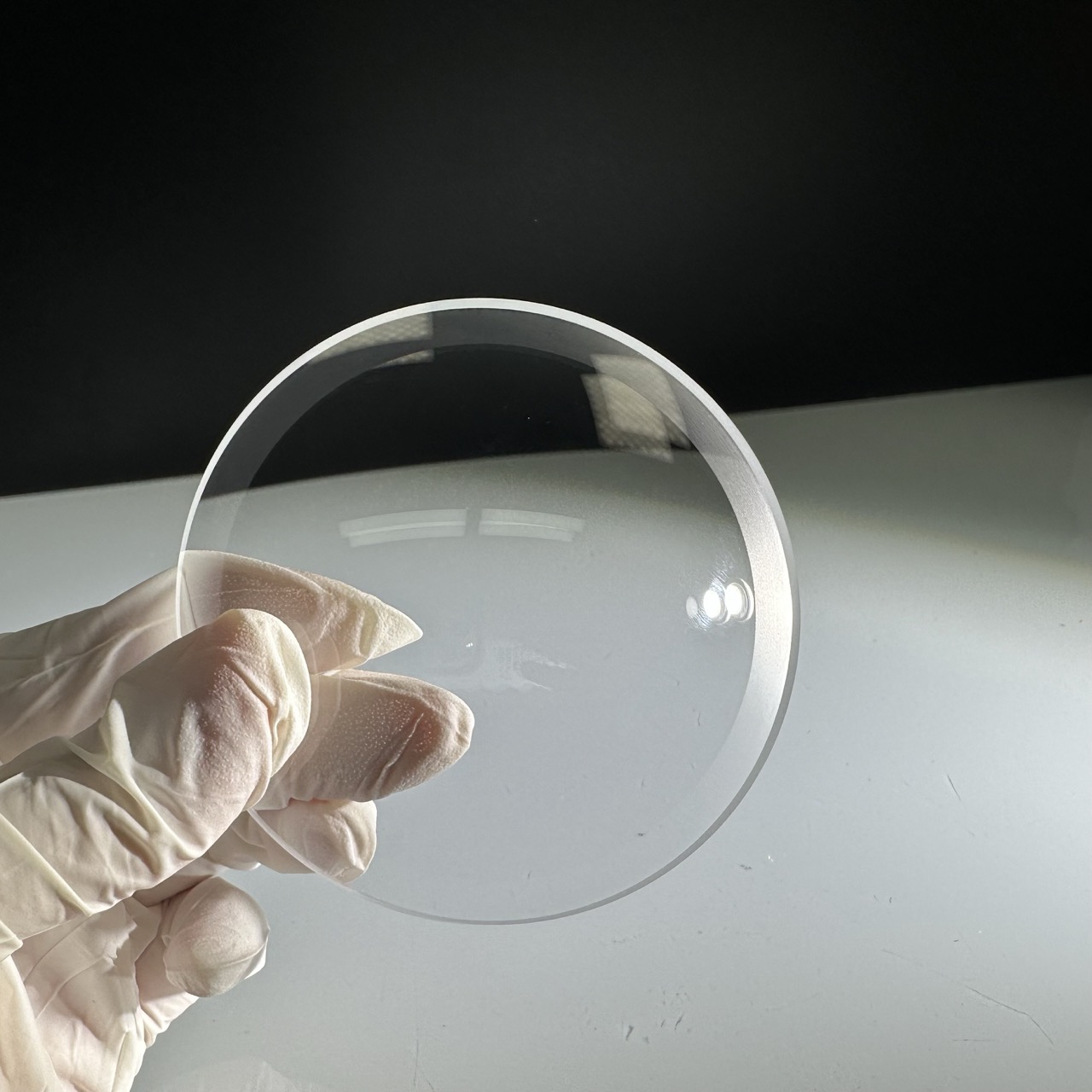

Auiliili Ata

Fa'ailoaina ole Silicon Carbide Ceramic Fork Arm/Lima

O leSilicon Carbide Ceramic Fork Arm/Limaose vaega fa'atautaia fa'agasolo ua atia'e mo faiga fa'aautomatika maualuga, fa'apitoa ile semiconductor ma alamanuia fa'apitoa. O lenei vaega o loʻo faʻaalia ai se mamanu faʻapitoa U-foliga e sili ona lelei mo le faʻaogaina o le wafer, faʻamautinoa uma le malosi faʻainisinia ma le saʻo saʻo i lalo o tulaga ogaoga o le siosiomaga. Fausia mai le silicon carbide ceramic maualuga-mama, letui lima/limae tu'uina atu ai le malosi fa'apitoa, fa'amautu fa'amama, ma le fa'ama'i.

A'o fa'asolo atu masini semiconductor i fa'ata'ita'iga sili atu ma fa'apalepale fa'apalepale, o le mana'oga mo vaega e leai se fa'aleagaina ma fa'amautu fa'amalama e matua taua. O leSilicon Carbide Ceramic Fork Arm/Limafa'afeiloa'i lenei lu'itau e ala i le ofoina atu o le fa'atupuina o vaega laiti, pito sili ona lamolemole, ma le fa'amaoni fa'atulagaina. Pe i le vafer felauaiga, substrate tulaga, po o robotic meafaigaluega ulu, o lenei vaega ua inisinia mo le faatuatuaina ma le umi o le ola.

O mafuaaga autu e filifili ai lenei meaSilicon Carbide Ceramic Fork Arm/Limaaofia ai:

-

La'ititi fa'alauteleina o le vevela mo le sa'o sa'o

-

Malosi maualuga mo le umi o le auaunaga

-

Tete'e atu i acids, alkalis, ma kasa toe gaoioi

-

Fegalegaleai ma ISO Vasega 1 potu mama siosiomaga

Fa'atonuga o le gaosiga ole Silicon Carbide Ceramic Fork Arm/Lima

O leSilicon Carbide Ceramic Fork Arm/Limao lo'o gaosia e ala i se su'esu'ega fa'agaioiga sima e fa'atonuina e fa'amautinoa ai le maualuga o meafaitino ma le tutusa o fua.

1. Sauniuniga Pa'u

O le faagasologa e amata i le filifilia o pauta carbide silikoni sili ona lelei. O nei pa'u e fa'afefiloi ma mea fa'apipi'i ma fesoasoani fa'aluma e fa'afaigofie ai le fa'apipi'iina ma le fa'ama'a. Mo leneitui lima/lima, β-SiC poʻo le α-SiC paʻu o loʻo faʻaaogaina e faʻamautinoa ai le maaa ma le faigata.

2. Fa'apena ma Fa'amuamua

Fa'alagolago ile lavelave oletui lima/limamamanu, o le vaega o loʻo faʻapipiʻiina i le faʻaogaina o le isostatic pressing, tui tui, poʻo le faʻasolo solo. O lenei mea e mafai ai mo geometries lavelave ma fausaga manifinifi puipui, taua mo le natura mama o leSilicon Carbide Ceramic Fork Arm/Lima.

3. Sintering maualuga-Sua

O le fa'amauina e faia i le vevela i luga a'e o le 2000°C ile vacuum po'o argon atmospheres. O lenei la'asaga e suia ai le tino lanu meamata i se vaega sima fa'ato'a fa'ama'a'a. O le sinteredtui lima/limamaua latalata-teoretical density, maua ai masini mataʻina ma vevela meatotino.

4. Fa'akomepiuta Sa'o

Post-sintering, leSilicon Carbide Ceramic Fork Arm/Limao'o i taimane olo ma CNC masini. Ole mea lea e mautinoa ai le mafolafola i totonu ole ± 0.01 mm ma fa'ataga mo le fa'aofiina o pu fa'apipi'i ma le su'eina o mea e taua ile fa'apipi'iina i faiga fa'aautomatika.

5. Fa'ai'uga o luga

O le fa'apolopolo e fa'aitiitia ai le gaogao o luga (Ra <0.02 μm), e mana'omia mo le fa'aitiitia o le fa'atupuina o vaega. E mafai ona fa'aoga fa'apipi'i CVD e fa'aleleia ai le tete'e o le plasma po'o le fa'aopoopoina o galuega fa'atino e pei ole amio fa'aanti-static.

I le faagasologa atoa o lenei faiga, e fa'aogaina faiga fa'atonutonu lelei e fa'amautinoa ai leSilicon Carbide Ceramic Fork Arm/Limafa'atino fa'atuatuaina i fa'aoga sili ona ma'ale'ale.

Parameter ole Silicon Carbide Ceramic Fork Arm/Lima

| Fa'amatalaga autu o le CVD-SIC Coating | ||

| SiC-CVD Meatotino | ||

| Fauga tioata | FCC β vaega | |

| Malosi | g/cm ³ | 3.21 |

| Malosi | Vickers maaa | 2500 |

| Tele o Saito | μm | 2~10 |

| Vailaau Mama | % | 99.99995 |

| Malosiaga vevela | J·kg-1 ·K-1 | 640 |

| Sulimation Temperature | ℃ | 2700 |

| Malosi Felexural | MPa (RT 4-point) | 415 |

| Young's Modulus | Gpa (4pt pi'o, 1300℃) | 430 |

| Fa'alauteleina o le vevela (CTE) | 10-6K-1 | 4.5 |

| Fa'avevela vevela | (W/mK) | 300 |

Fa'aoga ole Silicon Carbide Ceramic Fork Arm/Lima

O leSilicon Carbide Ceramic Fork Arm/Limao lo'o fa'aaogaina lautele i alamanuia e mana'omia ai le mama maualuga, mautu, ma le fa'ainisinia. E aofia ai:

1. Gaosiga Semiconductor

I le fausiaina o semiconductor, o leSilicon Carbide Ceramic Fork Arm/Limae fa'aaogaina e felauai ai masi fa'asolo i totonu o meafaigaluega fa'agaioiga e pei o potu etching, faiga fa'apipi'i, ma mea faigaluega su'esu'e. O lona tete'e vevela ma le sa'o sa'o e fa'amalieina mo le fa'aitiitia o le fa'aogaina o le wafer ma le fa'aleagaina.

2. Fa'aaliga Panel Gaosiga

I le OLED ma le LCD faʻaalia le gaosiga, o letui lima/limao lo'o fa'aogaina i faiga fa'apipi'i-ma-nofo, lea e fa'aogaina ai mea mata'eta'e mata'utia. O lona mamafa maualalo ma le ma'a'a maualuga e mafai ai ona fa'agaoioi vave ma mautu e aunoa ma le tete'e po'o le fa'afefe.

3. Optical ma Photonic Systems

Mo le fa'aogaina ma le fa'atulagaina o tioata, fa'ata, po'o ata meataalo, o leSilicon Carbide Ceramic Fork Arm/Limaofo atu le lagolago e leai se vibration, e taua tele i le fa'aogaina o le laser ma le fa'aogaina o su'esu'ega sa'o.

4. Aerospace & Vacuum System

I le aerospace opitika faiga ma masini gaogao, o lenei vaega e le-mamaneta, corrosion fausaga e mautinoa ai le mautu umi. O letui lima/limae mafai fo'i ona fa'agaoioi i totonu ole vacuum ultra-maualuga (UHV) e aunoa ma le alu ese.

I nei tulaga uma, o leSilicon Carbide Ceramic Fork Arm/Limae sili atu nai lo u'amea masani po'o isi polymer i le fa'amaoni, mama, ma le ola tautua.

FAQ ole Silicon Carbide Ceramic Fork Arm/Lima

Q1: O le a le tele o fafie o loʻo lagolagoina e le Silicon Carbide Ceramic Fork Arm / Lima?

O letui lima/limae mafai ona fa'apitoa e lagolago 150 mm, 200 mm, ma 300 mm wafers. E mafai ona fetuutuuna'i fa'ata'ita'iga o le tui, lautele o lima, ma pu e fetaui ma lau fa'aautometi fa'apitoa.

Q2: O le Silicon Carbide Ceramic Fork Arm/Lima e fetaui ma masini masini?

Ioe. O letui lima/limae fetaui lelei mo faiga fa'amama maualalo ma ultra-maualuga. E maualalo fua fa'amama ma e le fa'asa'olotoina ai ni pa'u, e lelei ai mo potu mama ma vacuum si'osi'omaga.

Q3: E mafai ona ou faʻaopoopoina faʻapipiʻi poʻo suiga i luga o le tui lima / lima?

E mautinoa lava. O leSilicon Carbide Ceramic Fork Arm/Limae mafai ona faʻapipiʻiina i le CVD-SiC, carbon, poʻo le oxide layers e faʻaleleia ai lona plasma resistance, anti-static properties, poʻo le maaa o luga.

Q4: E faʻapefea ona faʻamaonia le lelei o le tui lima / lima?

Ta'itasiSilicon Carbide Ceramic Fork Arm/Limae faia su'esu'ega fa'apitoa e fa'aaoga ai CMM ma le laser metrology meafaigaluega. E su'esu'eina le lelei o luga ile SEM ma fa'amatalaga e le fa'afeso'ota'i e fa'afetaui tulaga ISO ma SEMI.

Q5: O le a le taimi e taʻitaʻia ai faʻatonuga lima / lima masani?

Taimi ta'ita'i e masani lava mai le 3 i le 5 vaiaso fa'atatau ile lavelave ma le aofa'i. E avanoa le fa'ata'ita'iga vave mo talosaga fa'anatinati.

O nei FAQ e fa'amoemoe e fesoasoani i inisinia ma 'au fa'atau ia malamalama i gafatia ma filifiliga e maua pe a filifilia seSilicon Carbide Ceramic Fork Arm/Lima.

Faatatau ia tatou

XKH faʻapitoa i atinaʻe tekonolosi, gaosiga, ma faʻatau atu o tioata faʻapitoa faʻapitoa ma mea tioata fou. O a matou oloa e tautuaina mea fa'aeletonika mata, mea fa'atau eletise, ma le militeri. Matou te ofoina atu vaega opitika Safaira, ufiufi tioata telefoni feʻaveaʻi, Ceramics, LT, Silicon Carbide SIC, Quartz, ma semiconductor wafers tioata. Faatasi ai ma le tomai faʻapitoa ma meafaigaluega faʻapitoa, matou te sili atu i le gaosiga o oloa e le masani ai, faʻamoemoe e avea ma taʻutaʻua optoelectronic mea faʻatekonolosi atinaʻe.