Meafaigaluega Fa'amama mo le 4 Inisi-12 Inisi Safaira/SiC/Si Wafers Processing

Galuega Fa'avae

O le fa'agasologa o le fa'amama fa'amama e fa'agaoioia i vaega e tolu:

Fa'ali'i Saasaa: O se uili taimane (le tele o le grit 200-500 μm) e aveese ai le 50-150 μm o mea i le 3000-5000 rpm e fa'aitiitia vave ai le mafiafia.

Uli Lelei: O se uili sili atu (grit size 1-50 μm) e faʻaitiitia ai le mafiafia i le 20-50 μm i le <1 μm / s e faʻaitiitia ai le faaleagaina i lalo.

Faila (CMP): O le slurry kemikolo-mechanical slurry e faʻaumatia toega faʻaleagaina, ausia Ra <0.1 nm.

Mea Fa'atatau

Silicon (Si): Tulaga mo CMOS wafers, manifinifi i le 25 μm mo 3D fa'aputu.

Silicon Carbide (SiC): Manaomia uili taimane faʻapitoa (80% taimane concentration) mo le mautu vevela.

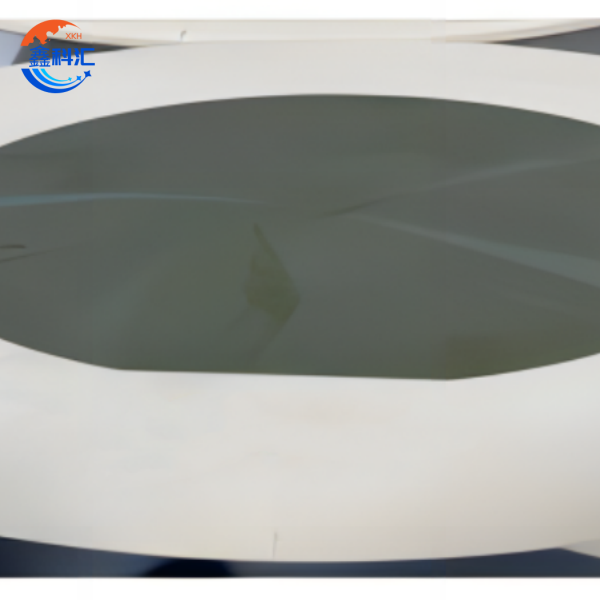

Safaira (Al₂O₃): Manifinifi i le 50 μm mo talosaga UV LED.

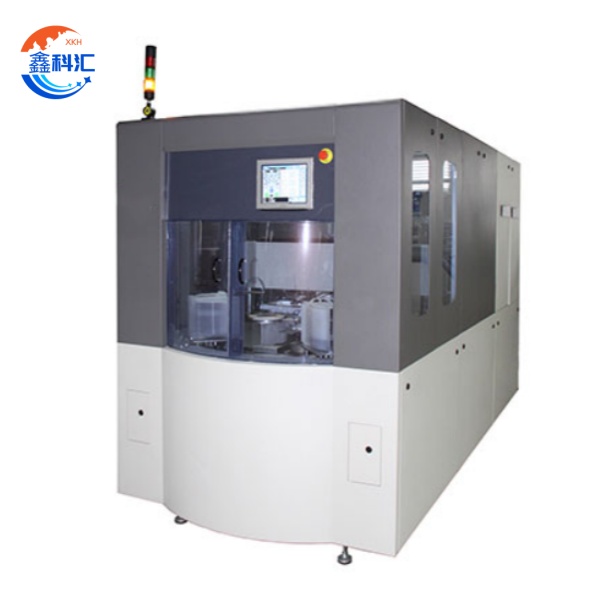

Vaega Autu System

1. Faiga olo

Lua-Axis Grinder: Tu'ufa'atasi le olo ma'ale'ale i se tulaga e tasi, fa'aitiitia le ta'amilosaga i le 40%.

Aerostatic Spindle: 0–6000 rpm va'aiga saosaoa ma le <0.5 μm radial runout.

2. Faiga Fa'afoeina Wafer

Vacuum Chuck: >50 N le malosi o lo'o taofiofia ma le ± 0.1 μm fa'atulagaina sa'o.

Robotic Arm: La'u 4–12-inisi sifi i le 100 mm/s.

3. Faiga Pulea

Laser Interferometry: Mata'ituina le mafiafia o le taimi moni (fa'aiuga 0.01 μm).

AI-Driven Feedforward: Va'ai le ofuina o uili ma fetuutuunai fa'amaufa'ailoga otometi.

4. Fa'alili & Fa'amamā

Ultrasonic Cleaning: Ave'ese vaega>0.5 μm ma le 99.9% lelei.

Suavai Fa'a'ona: Fa'amalieina le susu i le <5°C i luga a'e o le si'osi'omaga.

Manuia Autu

1. Fa'asa'o Maualuga Maualuga: TTV (Vaega Mafiafia Aofa'i) <0.5 μm, WTW (Vaega o le Mafiafia-Wafer) <1 μm.

2. Tu'ufa'atasiga Fa'atele: Fa'atasia le oloina, CMP, ma le fa'amauina o le plasma i le masini e tasi.

3. Mea Fesootaiga:

Silikon: Fa'aitiitiga mafiafia mai le 775 μm i le 25 μm.

SiC: Ausia <2 μm TTV mo talosaga RF.

Wafers Doped: Wafers InP-doped Phosphorus ma le <5% resistivity drift.

4. Smart Automation: MES tu'ufa'atasiga fa'aitiitia le sese a tagata i le 70%.

5. Malosiaga Lelei: 30% maualalo le faʻaaogaina o le eletise e ala i le toe faʻafouina o le taofi.

Talosaga Autu

1. Fa'apipi'i Fa'apitoa

• 3D ICs: Fa'amama fa'amama e mafai ai ona fa'aputu i luga sa'o le fa'aputuga (fa'ata'ita'iga, fa'aputuga HBM), ausia le 10x maualuga le bandwidth ma le 50% fa'aitiitia le fa'aogaina o le eletise e fa'atusatusa i fofo 2.5D. O meafaigaluega e lagolagoina le fusifusia hybrid ma le TSV (Through-Silicon Via) tuʻufaʻatasia, taua mo AI / ML processors manaʻomia <10 μm interconnect pitch. Mo se faʻataʻitaʻiga, 12-inisi wafers manifinifi i le 25 μm faʻatagaina faʻapipiʻi 8+ laulau aʻo tausia <1.5% warpage, taua mo masini LiDAR faiga.

• Fa'apipi'i Fa'amama: I le fa'aitiitia o le mafiafia o le wafer i le 30 μm, e fa'apu'upu'u le umi o feso'ota'iga i le 50%, fa'aitiitia le tuai o fa'ailo (<0.2 ps/mm) ma mafai ai le 0.4 mm ultra-thin chiplets mo SoCs feavea'i. O le faʻagasologa e faʻaogaina ai faʻamaʻi-taui algorithms e puipuia ai le warpage (> 50 μm TTV pule), faʻamautinoa le faʻatuatuaina i talosaga RF maualuga.

2. Malosiaga Faaeletonika

• IGBT Modules: Thinning i le 50 μm faʻaitiitia ai le vevela i le <0.5 ° C / W, faʻatagaina 1200V SiC MOSFETs e faʻaogaina i le 200 ° C vevela vevela. O a matou mea faigaluega e faʻaaogaina le tele o vaega o le olo (maofa: 46 μm grit → fine: 4 μm grit) e faʻaumatia ai le faʻaleagaina o lalo, ausia> 10,000 taamilosaga o le faʻalagolago i le uila. E taua tele lenei mea mo EV inverters, lea e 10 μm-mafiafia SiC wafers faʻaleleia le saoasaoa o suiga ile 30%.

• GaN-on-SiC Power Devices: Wafer thinning to 80 μm faʻaleleia le eletise eletise (μ> 2000 cm² / V·s) mo 650V GaN HEMTs, faʻaitiitia le gau o le faʻauluina i le 18%. O le fa'agasologa e fa'aogaina ai le fa'aogaina o le laser e taofia ai le ta'e i le taimi o le manifinifi, ausia le <5 μm pito kiliva mo RF power amplifiers.

3. Optoelectronics

• GaN-on-SiC LEDs: 50 μm sapphire substrates faʻaleleia le faʻaogaina o le malamalama (LEE) i le 85% (vs. 65% mo 150 μm wafers) e ala i le faʻaitiitia o le faʻaogaina o photon. Ole pulea ole TTV e sili ona maualalo ole masini (<0.3 μm) e fa'amautinoa ai le fa'aogaina o le fa'aogaina o le LED i le 12-inisi, e taua tele mo fa'aaliga Micro-LED e mana'omia <100nm le umi o le galu.

• Silicon Photonics: 25μm-mafiafia silicon wafers mafai ai le 3 dB/cm maualalo fa'aliga gau i ta'iala, e mana'omia mo 1.6 Tbps transceivers optical. O le faʻagasologa e tuʻufaʻatasia ai le faʻalelei o le CMP e faʻaitiitia ai le gaogao o luga i le Ra <0.1 nm, faʻaleleia le faʻaogaina lelei e 40% .

4. MEMS Sensors

• Accelerometers: 25 μm silicon wafers ausia SNR> 85 dB (vs. 75 dB mo 50 μm wafers) e ala i le faʻateleina o le faʻamaonia-mass displacement sensitivity. O la matou faiga fa'ato'aga lua e fa'amalieina le fa'alili o fa'amamafa, fa'amautinoaina e <0.5% le ma'ale'ale fa'asolo i luga -40°C i le 125°C. O talosaga e aofia ai le su'esu'eina o fa'alavelave tau ta'avale ma le su'esu'eina o gaioioiga AR/VR.

• Va'aiga O'omi: Fa'amama i le 40 μm e mafai ai ona fa'afua ai le 0-300 pa o fua fa'atasi ma le <0.1% FS hysteresis. O le fa'aogaina o le so'otaga le tumau (va'a tioata), o le fa'agasologa e 'alofia ai le gau o le wafer i le taimi o le togiina i tua, ausia le <1 μm le fa'apalepale maualuga mo masini IoT alamanuia.

• Fa'atekonolosi Fa'atekinisi: O a matou masini fa'ama'i mafi e fa'atasia ai le oloina fa'ainisinia, CMP, ma le plasma etching e fo'ia ai lu'itau o meafaitino eseese (Si, SiC, Sapphire). Mo se faʻataʻitaʻiga, e manaʻomia e le GaN-on-SiC le faʻaogaina o meaʻai (uila taimane + plasma) e faapaleni ai le maaa ma le faʻalauteleina o le vevela, ae o le MEMS e manaʻomia le laʻititi o le 5 nm e ala i le CMP polishing.

• Aafiaga o Alamanuia: E ala i le faʻamalosia o faʻamaʻi manifinifi, sili atu le faʻatinoga, o lenei tekinolosi e faʻauluina ai mea fou i AI chips, 5G mmWave modules, ma mea faʻaeletonika fetuutuunai, faʻatasi ai ma TTV tolerances <0.1 μm mo faʻaaliga gaugau ma <0.5 μm mo masini LiDAR masini.

Au'aunaga a le XKH

1. Fofo Fa'apitoa

Fa'atonu Fa'atonu: Fuafuaga o potu 4-12-inisi fa'atasi ma le fa'afuaina o le utaina ma le la'uina o uta.

Lagolago Doping: Fua masani mo tioata Er/Yb-doped ma InP/GaAs wafers.

2. Lagolago Fa'ai'uga

Fa'agasologa o Atina'e: Fa'ata'ita'iga e leai se totogi e fa'atautaia ma le fa'amalieina.

A'oa'oga Fa'alelalolagi: A'oa'oga fa'apitoa i tausaga ta'itasi ile tausiga ma fa'afitauli.

3. Fa'agaioiina o Mea e tele

SiC: Vafe manifinifi i le 100 μm ma Ra <0.1 nm.

Safaira: 50μm mafiafia mo faamalama leisa UV (transmittance> 92%@200 nm).

4. Au'aunaga e Fa'aopoopoina Tau

Tuuina atu: Uila taimane (2000+ wafers/ola) ma slurries CMP.

Fa'ai'uga

O lenei masini manifinifi wafer e tuʻuina atu le saʻo lelei o pisinisi, tele-material versatility, ma atamai faʻaautomatika, e matua taua tele mo le tuʻufaʻatasia 3D ma le eletise eletise. XKH 'au'aunaga fa'apitoa-mai le fa'avasegaina i le mae'a fa'agaioiga-fa'amautinoa e maua e tagata fa'atau le lelei o tau ma le fa'atinoina o galuega i le gaosiga semiconductor.